THE SITUATION

With the significant gas production potential in the Brazilian territory and increasing government investments aimed at boosting the competitiveness of this commodity for domestic consumption, Brazil has been gradually investing in its extraction and processing. In this context, more gas fields are being developed and pipelines for transporting production are being built or expanded.

This situation is no different for Brazil’s largest Oil & Gas operator. Year after year, the company has invested substantially in increasing or improving natural gas transportation routes. As a result, chemical products are needed to mitigate problems related to gas treatment or pipeline integrity. In this regard, DORF KETAL has a complete portfolio to meet any required applications.

Within this context, DORF KETAL was invited by the operator of the field referenced in this case study to recommend a chemical solution to inhibit corrosion that met the main technical requirements:

- Protect the system by specifying a corrosion rate by mass loss of less than 0.125 mm/year.

- Compatibility with the elastomers used in the process equipment.

- Low tendency to form or stabilize foam or emulsions.

For this case, the client required effective corrosion protection in a pipeline carrying a multiphase fluid containing water, condensation, and gas.

INTERNAL DEVELOPMENT

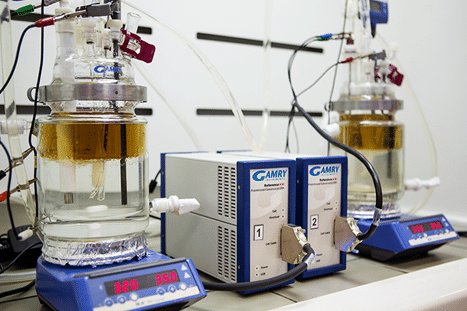

For this challenge, the team of specialists at DORF KETAL’s R&D center developed the GUARDIAN OG 203B product, which adequately met all the required technical specifications and achieved an excellent cost-benefit ratio. Currently, the DORF KETAL Research Center has a complete structure for molecule synthesis, performance testing of corrosion inhibitors via the Bubble test or RCA (rotating cage), and services related to corrosion monitoring when requested.

RESULTS

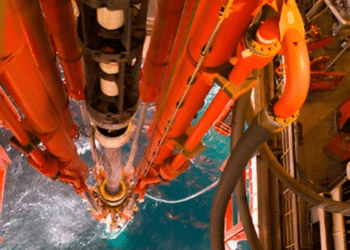

After internal development, GUARDIAN OG 203B was applied in the field, in a pipeline connected to a Brazilian offshore unit with the following characteristics:

- Platform: fixed.

- Water depth: 40 meters.

- Pipeline diameter: 24 inches.

- Pipeline length: 125 km.

- Fluid: Multiphase (gas, condensate, and water).

- Gas production: 8 MMm³/day.

- Temperature: 45°C.

- Pressure: 51 kgf/cm².

- CO₂ content: 0.37%.

- Injection point: Start of the pipeline.

After arriving at the onshore treatment station, the gas is separated from the water, condensed, and sent to the distribution station. The produced gas is intended for residential, vehicular, and industrial use.

The application of GUARDIAN OG 203B in the field was carried out through continuous injection at a dosage between 7–10 ppm, showing excellent performance according to the operator and engineers who oversaw the process. There was a significant reduction in the system’s corrosion rate, which was previously classified as moderate with the prior treatment and became classified as low with DORF KETAL’s treatment, presenting values below 0.125 mm/year.

VALUE GENERATION

The main benefits highlighted by the client from using the GUARDIAN OG 203B corrosion inhibitor were the reduction of the pipeline corrosion rate and the operator’s operational costs with chemical treatment and equipment maintenance. The use of GUARDIAN OG 203B helped the client ensure the integrity of the pipeline, avoiding potential production losses and extra expenses for equipment replacement. As a result, overall expenses with chemical treatment were reduced, ensuring that the client’s internal goals and expectations for the treatment were met.

The GUARDIAN OG 203B product is considered a market benchmark by the client regarding the treatment of multiphase pipelines.