INTRODUCTION

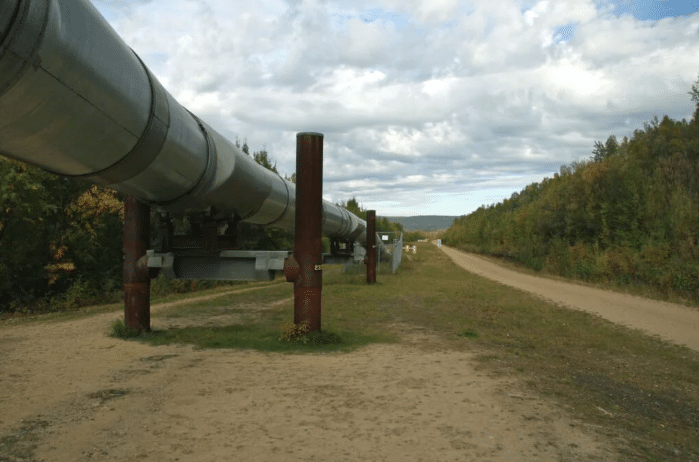

An onshore Oil and Gas Operator in Brazil faced a critical challenge related to internal corrosion in its pipelines, primarily caused by the presence of residual water in the transported oil. Continuous exposure to water promoted corrosive processes that compromised operational safety, increased maintenance costs, and raised the potential for environmental impact. In this context, an effective, safe, and economically viable solution for corrosion inhibition was sought.

Dorf Ketal, with its global expertise in chemical solutions for the oil and gas industry, was invited to participate in the selection process. The GUARDIAN OG 216B product demonstrated superior performance in laboratory tests, outperforming other commercial alternatives. The solution was successfully implemented, ensuring significant improvements in safety, efficiency, and asset preservation.

OPERATIONAL CONTEXT

The project was conducted in an onshore oil production field, where crude oil is transported through a pipeline following a primary separation stage. Despite initial processing, the oil still contained 0.6% water—enough to trigger significant corrosive processes inside the pipelines. The pipeline operated at a pressure of 70 kgf/cm² and a temperature of 50 °C, transporting approximately 6,000 m³ of crude oil per day.

Table 1. Operational Parameters of the Facility

| Property | Value |

| Gross oil production | 6.000 m³/day |

| Water content (BSW) | 0,6% |

| Operating pressure | 70 kgf/cm² |

| Operating temperature | 50 °C |

| Corrosion rate | 0,45 mm/year |

SOLUTION IMPLEMENTATION

Dorf Ketal’s proposal involved the application of GUARDIAN OG 216B, a corrosion inhibitor specifically developed for oil transport systems that contain water. The product underwent rigorous evaluations conducted by the Operator, where it exhibited excellent anticorrosive efficiency. Additionally, it demonstrated a high flash point, enhancing operational safety and full compatibility with the processed oil and existing infrastructure.

The applied dosage was 15 ppm, in continuous operation. The product’s formulation, combining efficacy and stability, directly contributed to preventing internal corrosion throughout the pipeline, even under adverse operating conditions.

RESULTS AND IMPACTS

The implementation of GUARDIAN OG 216B resulted in a significant reduction in the corrosion rate observed in the pipelines, decreasing from an average of 0.45 mm/year to 0.08 mm/year, ensuring the integrity of the assets.

The product fully met the performance indicators defined in the contract, particularly regarding improvements in safety and operational efficiency.

From an operational perspective, there was a reduction in the risks of mechanical failures and unplanned shutdowns, along with the prevention of leaks that could cause environmental damage. The product’s high flash point also helped mitigate flammability risks. Economically, the adoption of the inhibitor avoided expenses related to corrective maintenance, replacement of pipeline sections, and environmental penalties.

STRATEGIC CONCLUSION

This case highlights the effectiveness of Dorf Ketal’s chemical solutions, emphasizing the importance of selecting appropriate specialized products for critical challenges in oil and gas operations. In addition to superior technical performance, GUARDIAN OG 216B stood out for its safety, compatibility, and positive cost-benefit ratio.

The partnership established with the client also highlighted the value of technical support provided, the agility of testing, and the ability to customize solutions. In an increasingly demanding market, the ability to deliver swift and effective responses becomes a strategic differentiator. This case study positions Dorf Ketal as a reliable and innovative supplier for maintaining asset integrity in challenging environments.