A company operating in the Western Canadian Sedimentary Basin (WCSB) faced declining injection rates in a water disposal well due to scale buildup in the formation and tubing string. Enviro-Syn® BSD-40E™ was selected over mechanical milling and hydrochloric acid (HCl) treatment to minimize downtime and associated costs. The Enviro-Syn® BSD-40E™ treatment eliminated the need for a workover rig and was specifically formulated to handle barium sulfate scale. The results showed that the average injection rate doubled and remained stable for at least 45 days following the treatment.

CHALLENGE

The operator observed a significant decline in injection rates in a water disposal well due to barium sulfate scale accumulation. Barium sulfate (BaSO₄) is one of the most challenging scales to remove, causing reduced well conductivity and equipment contamination, which lowers injection rates in disposal wells. Barium sulfate also contains naturally occurring radioactive material (NORM), making surface handling of produced fluids challenging. As a result, in-situ treatments are often preferred, using either mechanical or chemical means for removal.

However, mechanical removal is expensive because it requires a workover rig or coiled tubing unit, typically leading to several days of downtime. Chemically, barium sulfate scale is insoluble in HCl, making alternative chemistries necessary. Barium sulfate scale also tends to reprecipitate once dissolved, which can further exacerbate production and contamination issues.

SOLUTION

Enviro-Syn® BSD-40E™ was designed to dissolve sulfate scales and possesses unique properties that make it ideal for removing deposits in water disposal wells. It can dissolve large quantities of barium sulfate scale while reducing sulfate particle size to minimize reprecipitation after dissolution. It also features a lower activation temperature and pH than other products on the market, making it safer to handle and easier to apply.

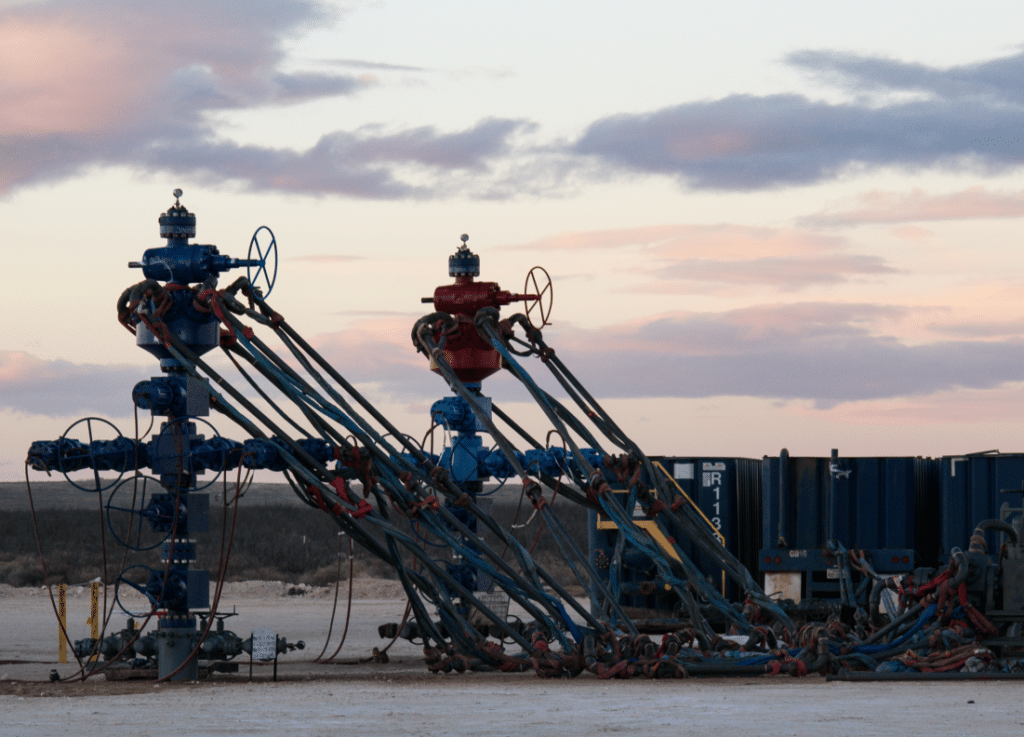

Due to the low bottomhole temperature, produced water was heated to 60°C (140°F) and injected the day before treatment to raise the temperature of the formation and tubing. A total of 4 m³ (1,056 gal) of Enviro-Syn® BSD-40E™ was heated to 90°C (194°F) using an oil heater and injected via a pressure truck in 1 m³ (264 gal) increments, with 0.5 m³ (132 gal) of fresh water spacers displaced to the perforations for soaking. An additional 1 m³ (264 gal) of produced water was injected twice separately to push the Enviro-Syn® BSD-40E™ further into the formation, followed by a shutdown and soaking period. The well was left to soak for approximately 12 hours before resuming injection the following day.

RESULTS

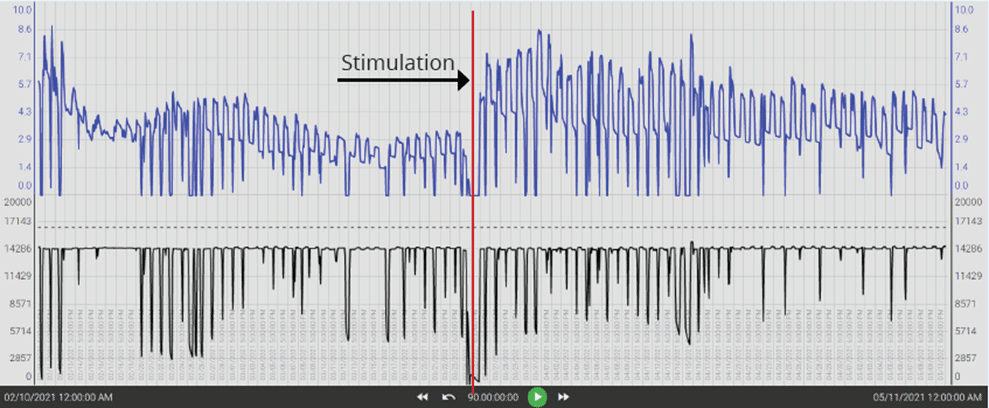

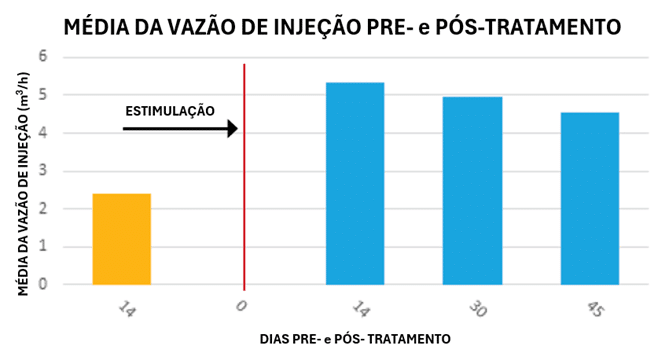

Disposal well injection rates were compared before and after treatment with Enviro-Syn® BSD-40E™ (Figures 1 and 2), while maintaining constant injection pressure. Post-treatment injection rates were more than double those observed prior to the stimulation treatment and remained stable throughout the 45-day monitoring period.

In addition to successfully increasing injection rates, the treatment cost using Enviro-Syn® BSD-40E™ was approximately ten times lower and required only one day of downtime, compared to the typical four days for conventional mechanical remediation.

The operator has since adopted Enviro-Syn® BSD-40E™ for regular use in disposal wells to address any type of barium sulfate scale buildup.

___________________________________________________

____________________________________________________