INTRODUCTION

This Case Study evaluates the Compatibility of Modified Acids for Reverse Osmosis Membrane Cleaning.

Two acids from the Enviro-Syn™ Modified Acids portfolio, developed by the Fluid Energy Group, were used in this compatibility study to determine their suitability and compatibility as acidic cleaning agents for polyamide reverse osmosis (RO) membranes commonly used in high-purity water production.

HCR-PLUS™, A MODIFIED HYDROCHLORIC ACID

HCR-PLUS is a proprietary and environmentally responsible Modified Acid™ that minimizes hazardous exposure levels, corrosion rates, and negative HSE (Health, Safety, and Environment) properties of commonly used acids while offering excellent performance in penetration, solubilization, and scale removal. HCR-PLUS is NSF-60 approved for potable water applications in the United States.

ENVIRO-SYN® HCR-3000®, A SYNTHETIC ORGANIC ACID

Enviro-Syn HCR-3000 is a proprietary and environmentally responsible Synthetic Acid™ product that minimizes the hazardous exposure levels, corrosion rates, and negative HSE properties of hydrochloric acid (HCl) while maintaining the positive aspects of solubilization capacity and reaction rates.

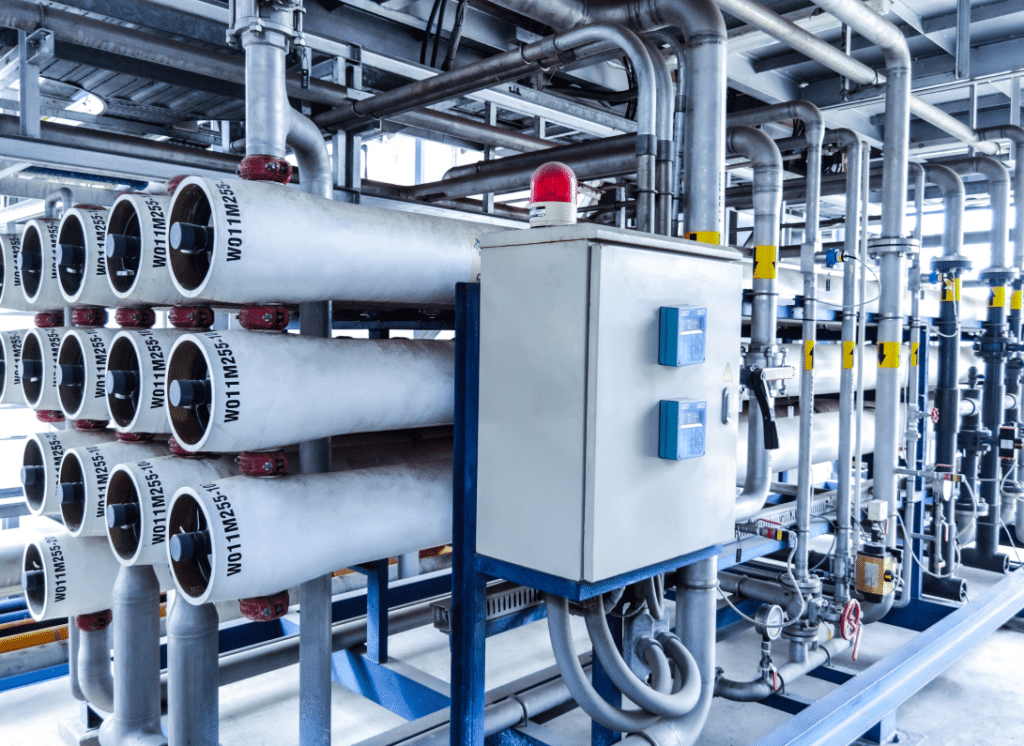

STUDY

Three RO membrane manufacturers were selected to test the cleaning solutions: brackish water elements from Dupont Filmtec and Suez, and a seawater element from Hydranautics.

- Dupont Filmtec BW-30-4040, serial number T9580567

- Suez MUNI-RO 400-HR-WT, serial number 220312043

- Hydranautics SWC5-LD, serial number 13153755

The operating parameters specified by the manufacturers for these membranes are pH 2–11 for general use and pH 1–13 for cleaning purposes, with the latter having a recommended exposure time of no more than 30 minutes.

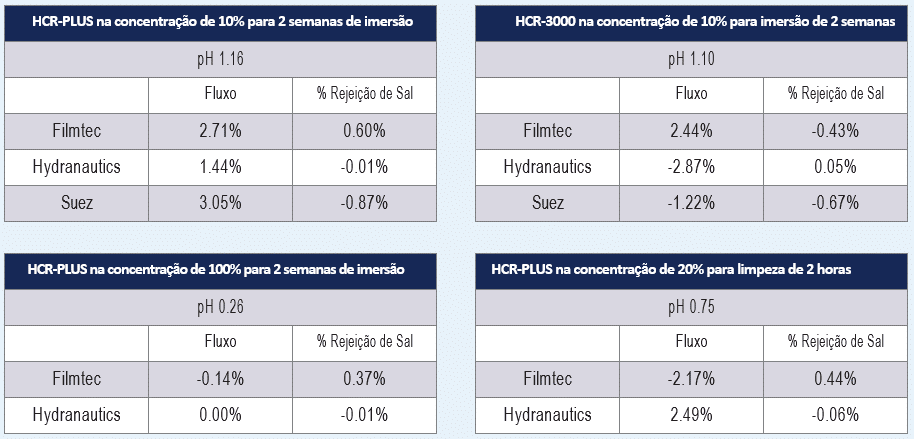

The goal of the test was to stress the membranes by extending exposure time and increasing acid strength beyond the recommended operational concentrations, to measure the effect and potential for membrane damage. The tests performed were:

(1) Two-week membrane soak at 10% and 100% concentration of the cleaning product before performing a saline water test.

(2) Two-hour cleaning run at 10% and 20% concentration of the cleaning product before performing a saline water test.

TEST METHOD

Flat-sheet membrane cell testers were used for this study. A single sheet from each Reverse Osmosis element was selected and cut into 4″ x 2″ coupons, each with an active membrane area of 3.5″ x 1.5″ exposed for testing.

Before acid exposure, each membrane sample was soaked in deionized (DI) water for 24 hours and then tested in a standard saline solution (2000 ppm NaCl at pH 7.8) at 225 psi to establish baseline membrane performance. Measurements of membrane flux and salt passage in the permeate were taken after 50 minutes (the first 30 minutes were discarded to allow membrane stabilization). After acid exposure in the tests described above, followed by DI water rinsing until all cleaning solutions were removed, the membranes were subjected to the same standard saline test.

Flux and salt passage in the permeate were measured again to provide pre- and post-acid exposure performance data.

RESULTS

Results are expressed as a percentage variation between pre- and post-acid exposure. A variation greater than -5.0% represents a greater-than-expected performance reduction, which may be attributed to test precision and uncontrolled external factors such as small ambient temperature variations.

Flux expresses the rate at which water permeates a reverse osmosis membrane. Typical measurement units are gallons per square foot per day (GFD or GSFD).

Salt Rejection measures the amount of salt passing through the membrane in the permeate flow instead of being rejected into the concentrate flow.

INTERPRETATION AND CONCLUSION

All stress test results are within the 5% variation limit applied, showing no significant changes in permeate flux across the tested reverse osmosis membranes. Salt Rejection varies by less than 1%, demonstrating no observed salt slippage beyond normal and expected diffusion. This means no significant changes in membrane integrity were observed after exposure of various commonly used reverse osmosis membranes to Enviro-Syn Modified Acids HCR-PLUS and HCR-3000.

Furthermore, significant overdosing of HCR-PLUS and prolonged exposure time, well beyond manufacturer recommendations, appear to have no meaningful impact on the integrity of the tested RO membranes. Refer to the two-week soak and two-hour 20% tests.