The Problem

One of the diesel storage tanks at a refinery processing high-sulfur crude oils from the Middle East, Iran, and West Africa unexpectedly failed the copper strip corrosion test. The fuel received the same processing (hydrotreatment) as the rest of the tank battery, all of which met the copper corrosion specification, but this particular 19,300 MT tank only achieved a 2C rating. Contamination by H₂S was diagnosed as the cause. Dorf Ketal already supplied treatment and process support to other refinery applications and maintained an on-site inventory of H₂S scavenger, so the local Dorf Ketal representative was consulted for recommendations.

Laboratory analysis indicated approximately 4–5 ppm of H₂S in the stored fuel. Based on prior experience with its H₂S scavengers in other high-sulfur crude blends, Dorf Ketal recommended 15–20 ppm of H₂S scavenger per ppm of H₂S, corresponding to an average dosage of 60–80 ppm for the contaminated tank.

The refinery laboratory evaluated a sample collected from the tank, confirming a copper strip corrosion rating of 2C. When a sample treated with 60 ppm of Dorf Ketal’s H₂S scavenger achieved a passing rating, the laboratory recommended treatment at 60–70 ppm to meet refinery specifications.

Treatment Methodology

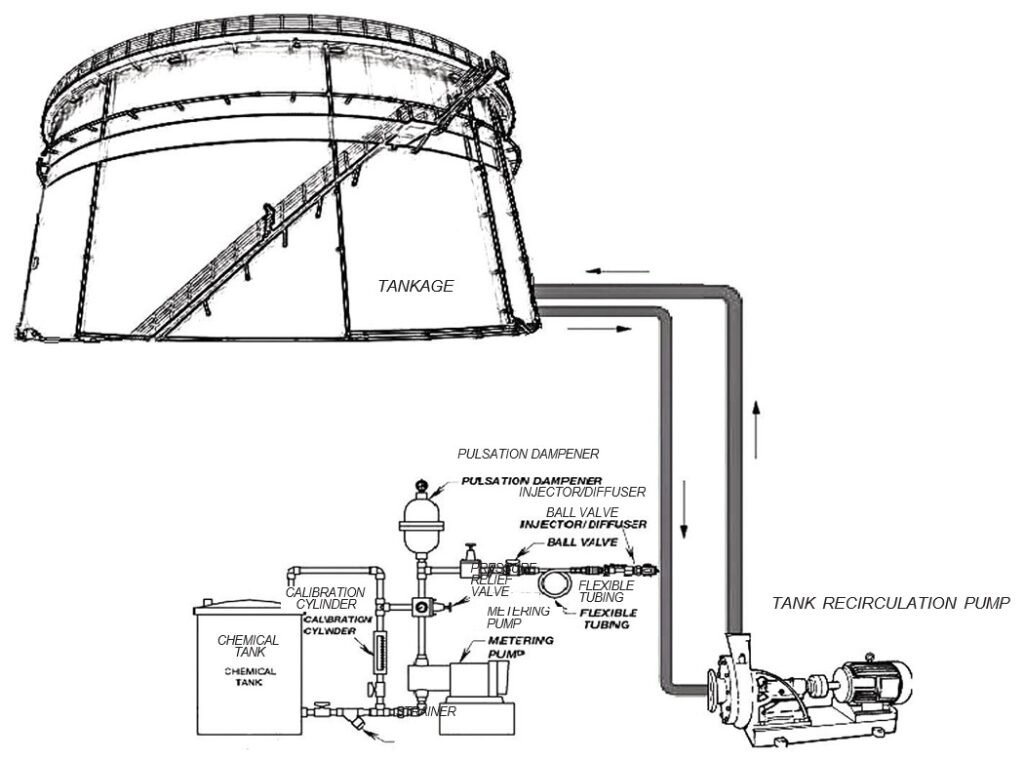

The chemical was injected into the suction of the tank recirculation pump using a skid-mounted system (Figure 1) consisting of a storage tank, calibration cylinder, dosing pump, and related hardware. To ensure sufficient mixing efficiency and contact, Dorf Ketal recommended a minimum of 10–12 hours of recirculation after injecting the required scavenger volume.

Figure 1 – Schematic diagram of H₂S scavenger dosing system.

Actual recirculation lasted 14–16 hours, with additional agitation provided by the tank’s side-entry mixers. The dosage required to treat 19,300 MT of contaminated diesel and meet the refinery’s target specification was 74.6 ppm of H₂S scavenger.

Results

Treatment with Dorf Ketal’s H₂S scavenger enabled the refinery to sell the treated fuel at contract prices, without reprocessing or additional storage costs, achieving a 1000% return on investment in treatment.

Performance Analysis

Blending off-spec fuels with higher-quality products is not always the most profitable solution. In many cases, chemical treatment is a better alternative that can improve operational margins, avoid costly rework and inventory expenses, and prevent delivery delays.