Introduction

A Refining Unit of the largest Petroleum Refining Company in Latin America, with a processing capacity of 434,000 barrels per day, launched a public tender for chemical decontamination services prior to a General Maintenance Shutdown.

The bidding criteria included the evaluation of the following indicators:

- Applied technology

- Proven previous experience

- Minimal impact and best practices in Health, Safety and Environmental aspects

- Shortest equipment release time

- Price

The scope of service included the chemical decontamination of the following equipment:

- Desalters

- Atmospheric Tower

- Vacuum Tower

At the end of the bidding process, Dorf Ketal was declared the winner and awarded the contract to execute the service.

Fundamentals of Chemical Decontamination of Industrial Equipment

Objective

The chemical decontamination procedure for industrial units in the hydrocarbon chain is of utmost importance and is directly related to productivity, health, safety, and environmental (HSE) aspects. In a refinery, equipment cannot be accessed before being safely released, which means ensuring the absence of toxic and flammable compounds so that workers can perform maintenance activities without risk. Moreover, this procedure allows for faster equipment release, reducing unit downtime and, consequently, maintenance costs.

Phases

The first phase consists of PRE-ENGINEERING activities, including site visits. In this stage, the necessary equipment and the amount of chemicals required for decontamination are determined, along with the definition of injection points for chemicals and monitoring points for toxic gases and explosivity.

Next, the classes of chemical products to be used are defined, such as high-performance degreasers, degassing agents, and stabilizers.

The procedure comprises two main stages: degreasing and degassing. Depending on the equipment type, additional stages may be required, as agreed with the client.

The degreasing stage consists of applying a combination of degreasing agents and solvents with organic and/or inorganic characteristics in optimal concentrations for each process unit, combined with controlled temperature and dynamic contact.

The degassing stage involves the use of degassing agents in conjunction with steam (as a carrier medium) to remove gases and contaminants impregnated inside the equipment.

Degreasing is monitored through periodic sample collections for qualitative and quantitative analysis of removed sludge, as well as temperature tracking.

For degassing, internal temperature and pressure are monitored, along with the drainage of condensate formed during chemical purging. The progress of degassing is periodically analyzed using gas detectors to measure hydrocarbon and H₂S levels.

Benefits

The main benefits for the Refinery resulting from the chemical decontamination process using Dorf Ketal’s methodology include:

- Reduced release time for inspection and maintenance activities.

- Improved HSE conditions due to enhanced industrial hygiene.

- Reduction of solid residues of organic/inorganic nature.

- Safe and sanitary conditions for confined space entry.

- Safe equipment opening without risk of spontaneous combustion, especially in the Vacuum Tower.

Results

- Equipment released 2 days ahead of the minimum contractual expectation.

- Zero occurrences related to occupational health or environmental aspects.

- Equipment released with zero indicators of unhealthiness or hazard conditions.

- No incidents or accidents, maintaining integrity of personnel and equipment.

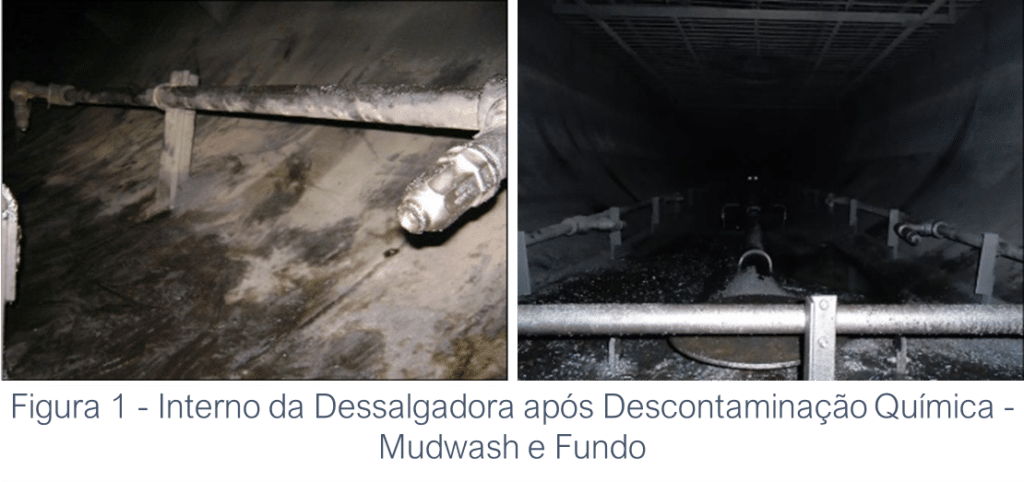

The following are photographic records of the equipment internals after opening during inspection:

The images show the excellent outcome of Dorf Ketal’s Chemical Decontamination process. The condition of the mudwash distribution nozzles and column trays was so clean that maintenance was easily performed, saving significant time and costs in equipment considered critical to the shutdown schedule. Without this procedure, the release time would have been 3 to 5 days, whereas Dorf Ketal delivered the equipment in 24 hours.

This work strengthened Dorf Ketal’s credibility with the client, generating new opportunities for similar services in other process units, such as FCC and HDT.