INTRODUCTION

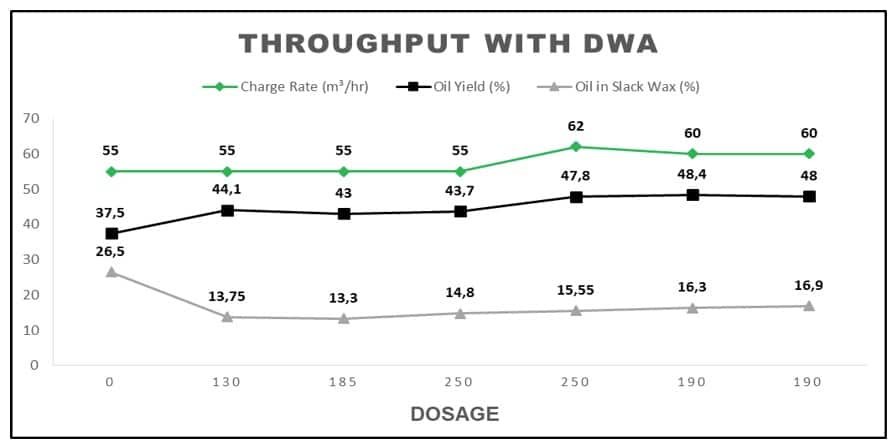

A refinery in Turkey experienced difficulties processing Heavy Raffinate in its MEK solvent dewaxing unit due to high oil content in paraffin wax and elevated refractive index values. The feedstock originated from the Furfural Extraction Unit. The maximum throughput achieved with the Heavy Raffinate feed was approximately 55 m³/h with one of the filters under maintenance. The base oil yield was about 68% of the feed rate. The oil content in paraffin wax was approximately 26.6%, and the refractive index was 1.4482.

PROPOSED SOLUTION

The Heavy Raffinate with a viscosity of 10.06 cSt was treated with Dorf Ketal’s Dewaxing Aid. A three-day test was conducted with the chemical product, which was extended due to the satisfactory results obtained.

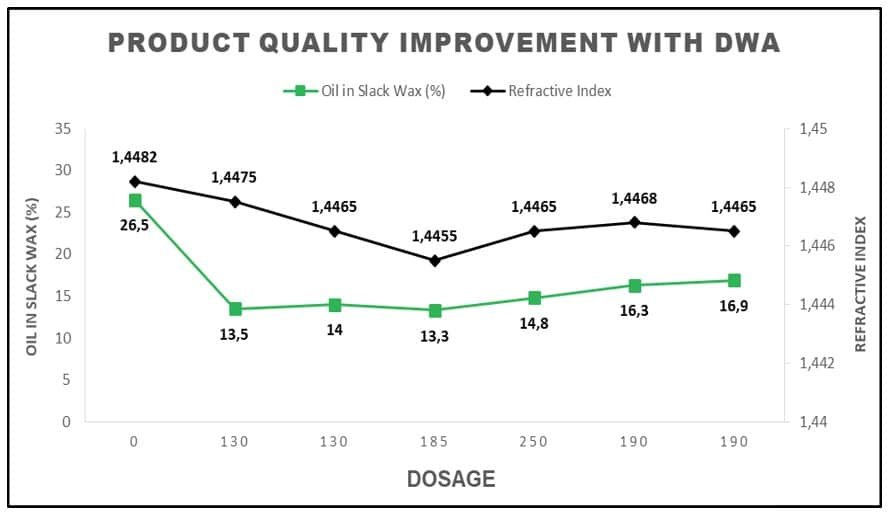

During the treatment period, the dosage was optimized and product quality improved significantly. This improvement is shown in Figure 2.

TEST RESULTS

After dosing the additive, the oil yield improved to about 80% of the unit feed rate, and the oil content in paraffin wax decreased to an average of 13.75%. The refractive index improved to an average of 1.4470. With higher dosages, results were even better.

CONCLUSION

Dorf Ketal’s Dewaxing Aid proved effective in improving oil yield and reducing the oil content in paraffin wax. The oil in paraffin wax was reduced by nearly 45% compared to the untreated condition. The Dewaxing Aid also helps improve filtration rates, resulting in higher throughput and consequently greater profitability for the processing unit.

For more information, please contact your nearest Dorf Ketal specialist. A process analysis will be carried out first, followed by a customized recommendation to maximize results.