INTRODUCTION

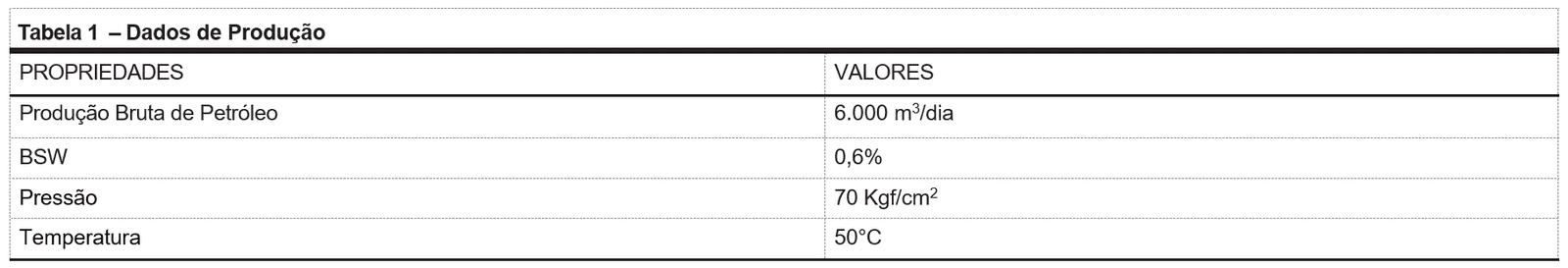

An onshore oil and gas field sends production from its wells to a separation station, where the primary oil processing takes place. After separating water and gas, the specified crude oil is transported via pipeline to the storage terminal and then forwarded to the refinery. The presence of a small percentage of water in the oil transported through the pipeline required the operator to protect the line against corrosion, making it necessary to use a corrosion inhibitor product.

The operating company invited Dorf Ketal to recommend a product to be tested and approved in its laboratory and to participate in the bidding process. Dorf Ketal recommended the DEFENDER™ OG 216B product, which demonstrated the best cost-benefit ratio and won the tender, initiating pipeline treatment to prevent corrosion.

The DEFENDER™ OG 216B product was continuously injected into the crude oil at an average dosage of 15 ppm and showed excellent performance, fully meeting the contractual expectations.

The main benefits provided by the use of DEFENDER™ OG 216B were the reduction of corrosion in the pipeline carrying the specified oil and the increase in operational safety due to the product’s high flash point.

The use of DEFENDER™ OG 216B helped the operator protect the pipeline from corrosion, preventing production losses and avoiding environmental damage from potential leaks.

STARTING POINT

Due to the presence of residual water in the treated crude oil, the field operator needed to apply a corrosion inhibitor to protect the pipeline that transports the oil to the storage terminal.

PERFORMANCE OBSERVED

DORF OG 216B reduced pipeline corrosion, meeting the client’s expectations for the treatment. In addition, it contributed to increased operational efficiency and helped prevent environmental damage from potential leaks.