INTRODUCTION

A major Exploration and Production (E&P) operator in Latin America conducted a performance-based bidding process for one of the country’s largest production units. DORF KETAL was declared the winner of this bidding process. The treatment proposed and currently implemented in the unit has resulted in a significant reduction in chemical consumption, leading to a substantial decrease in daily chemical treatment costs and logistics expenses.

The Production Unit analyzed in this study is recognized as one of the largest in Latin America, with a gross production of approximately 300,000 barrels of oil equivalent (BOE) and a global bottom sediment and water (BSW) content of around 70%. The platform operates at a water depth of 1,350 meters and produces crude oil with an API gravity of 17°. The final specifications for the treated oil require a BSW of 1% (with a desirable level of 0.5%) and a maximum salinity of 570 parts per million (ppm), which should be reduced to 285 ppm for offloading.

THE CONTRACTING PROCESS

In the bidding process discussed in this study, participating companies proposed various products for treating the Production Unit.

In performance-type contracts, the awarded company is required to supply all necessary chemical products, referred to as the “basket,” using the dosages proposed during the bidding process. These dosages are subsequently confirmed through laboratory or field-testing, as determined by the contracting company. It is important to note that proposed dosages cannot be increased later, as doing so may result in significant fines.

Typically, in this type of contract, the end client requests quotations for both commodity and specialty products. Since global contracts for commodity supplies are already in place, the contracting company has the option to decide whether it is more advantageous to utilize the performance contract or the global agreement for these products.

THE DORF KETAL CONTRACT

In the bidding process referenced in this study, the participating companies proposed the following products for treatment of the Production Unit:

- Demulsifier

- Flow improver

- Topside scale inhibitor

- Oil-side corrosion inhibitor

- Polyelectrolyte

- THPS-based biocide

- Continuous biocide

The first stage involved the internal development of these products at the Research, Development, and Innovation (R&D&I) Laboratory located in Nova Santa Rita, RS, Brazil.

The scale inhibitor was developed in accordance with the technical specifications required by the user and the approval protocols of the client’s reference laboratory, which included rigorous testing under subsea conditions. The processing conditions of the Unit and the quality of the produced water presented significant challenges regarding the scaling potential of calcium carbonate, as well as calcium and barium sulfates.

Despite these demanding conditions, DORF KETAL successfully developed a competitive product with excellent field performance, utilizing its proprietary bases for scale inhibitors. These inhibitors are composed of bifunctional polymeric molecules that alter the crystalline structure of the formed salts while neutralizing the charges that lead to agglomeration under severe temperature and salinity conditions.

To develop the flow improver and demulsifier, bottle tests were conducted to create a product that meets the industry’s needs. The final formulation for this type of treatment can only be established through bottle tests using fresh crude oil, which must be performed directly on board the Production Unit.

DORF KETAL utilizes a modern evaluation and selection process for demulsifiers and flow improvers, employing optical techniques to monitor the resolution of the oil-water interface. We optimize dosages using equipment that simulates the operational conditions of the platform’s oil-water separator.

The oil-side corrosion inhibitor was developed using the Bubble Test, which evaluated its effectiveness under the specified technical conditions of the project. The formulation was designed to prevent foaming and the formation of emulsions, while ensuring it does not negatively impact the platform’s oil and water treatment processes. It is fully compatible with other proposed treatment products. This corrosion inhibitor, specifically developed for the platform, features a long stearic chain that provides excellent surface coverage and strong adhesion to metallic substrates

The polyelectrolyte was suggested only as a backup option, as the Unit historically lacked consumption data for this product category.

Moreover, DORF KETAL has significant experience demonstrating that its oil treatment with demulsifiers effectively clarifies the separated water, often making the addition of a polyelectrolyte unnecessary.

Biocide products, whether THPS-based or continuous, are treated as commodities and have been proposed in accordance with the technical specifications outlined during the bidding process.

RESULTS & VALUE GENERATION

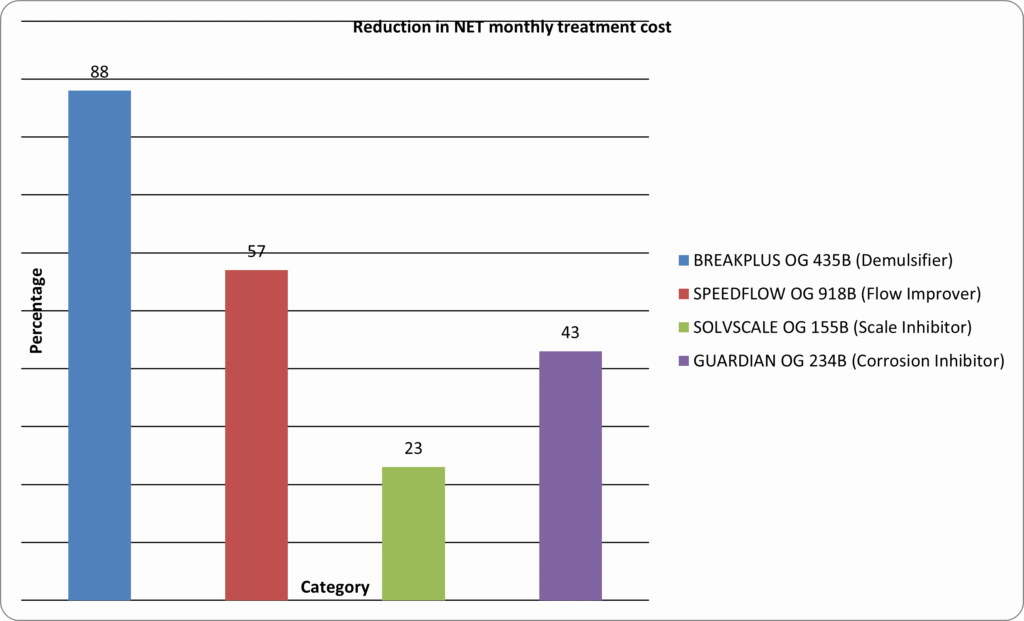

The dosages and prices proposed by DORF KETAL led to an approximate 51% reduction in total chemical treatment costs for the platform.

Furthermore, the lower dosages required for certain products reduced the volume of cargo that needed to be handled and stored on board. This was a significant advantage for the client, as the platform has limited storage capacity, thereby minimizing Health, Safety, and Environment (HSE) risks.

Additionally, DORF KETAL received positive feedback regarding the transition to its chemical program. The client noted that the new treatment delivered more effective performance than the previous one, especially in terms of oil and water quality parameters.

Source: Technical Marketing Editorial – DORF KETAL