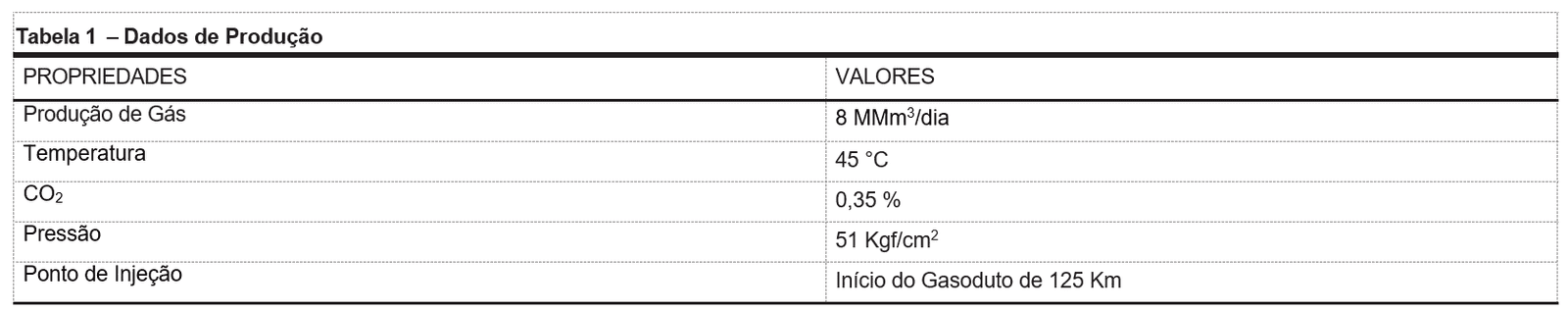

In one of the largest offshore non-associated natural gas fields on the Brazilian coast, a fixed platform located 10 km from shore and in 40 meters of water depth needed to transfer its production to an onshore treatment station through a 24-inch (60.96 cm) diameter, 125-kilometer-long pipeline. The transported fluid was multiphase, consisting of gas, condensate, and water, which significantly increased the corrosive potential of the system, making an effective corrosion-inhibition treatment essential. At the onshore treatment station, gas was separated from water and condensate and then directed to the distribution station. The produced gas was destined for residential, vehicular, and industrial consumption.

In this context, Dorf Ketal was invited by the field operator to recommend a chemical corrosion-inhibition solution that would meet the following requirements:

- Compatibility with elastomers used in process equipment.

- Low tendency to foam formation or emulsion stabilization.

- System protection with corrosion-rate specification below 0.125 mm/year.

To address this challenge, Dorf Ketal’s team of specialists developed the product DORF OG 203B, which met all requirements and, due to its excellent cost-benefit ratio, was approved for field application.

The DEFENDER OG 203B product was continuously injected at a dosage between 7–10 ppmv, delivering excellent performance. A significant reduction in the system’s corrosion rate was observed, which was previously classified as moderate under the former treatment and became classified as low with Dorf Ketal’s treatment.

The main benefits achieved with the use of DEFENDER OG 203B were the reduction of corrosion rate in the gas pipeline and the decrease in the operator’s chemical-treatment and maintenance costs.

The use of DORF OG 203B helped the customer ensure pipeline integrity, avoiding possible production losses and additional expenses related to equipment replacement.

Starting Point

The customer required effective corrosion protection in a pipeline transporting a multiphase fluid containing water, condensate, and gas.

Observed Performance

DORF OG 203B reduced corrosion in the gas pipeline and the costs associated with chemical treatment, fully meeting the customer’s expectations for the application.