INTRODUCTION

Following the discovery of the pre-salt fields in Brazil, a major effort was made to enable large-scale production. The specific characteristics of Brazilian offshore reservoirs, combined with high processing temperatures, favor the formation of scale, mainly calcium carbonate.

The deposition of these salts—especially in heat exchangers, coolers, and boilers—can cause severe operational problems, including partial or total blockage of lines, inefficient water treatment, increased operating costs, and even production losses.

Operating under high salinity conditions (around 200,000 ppm NaCl), the largest pre-salt operator in Brazil faced significant production losses and elevated treatment costs in certain production units, where the previous scale inhibitor technology required dosages as high as 1,000 ppm.

INTERNAL DEVELOPMENT

The major Brazilian operator requested DORF KETAL to develop a topside scale inhibitor for its pre-salt production units. All development testing was carried out at the DORF KETAL R&D laboratory in Nova Santa Rita, Brazil. The company’s scientific team developed specific polymeric molecules tailored for the application. The following were the key boundary conditions for the requested solution:

- Temperature: 130°C

- Pressure: 8 bar

- Salinity: 100,000 ppm

- Brine compatibility: up to 20,000 ppm

After extensive testing to identify the optimal chemical base for this specific application, DORF KETAL developed SOLVSCALE OG 179B, a topside scale inhibitor designed for pre-salt production systems.

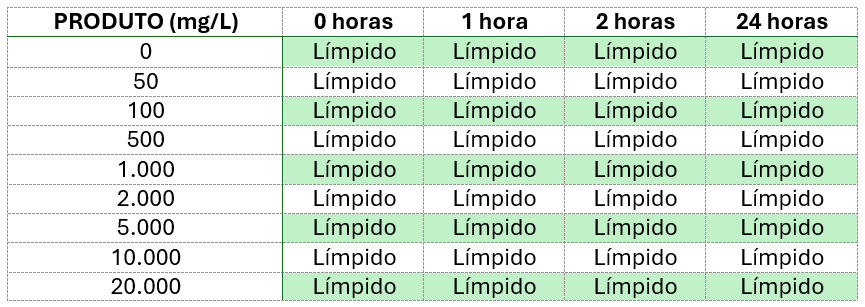

In the first stage, the product underwent brine compatibility testing, evaluating its behavior with calcium ions present in the system. Bottle tests were performed using synthetic water with the same composition as the produced water, and the product was considered approved since no turbidity or precipitation was observed during the test.

Dynamic efficiency testing was conducted using a Dynamic Scale Loop (DSL), which consists of two independent pumps that feed separate anionic (scaling anions only) and cationic (scaling cations only) brine streams at a rate of 10 mL/min. These streams meet inside a 1 m-long, 0.5 mm ID tubing section where pressure is monitored to detect scale formation.

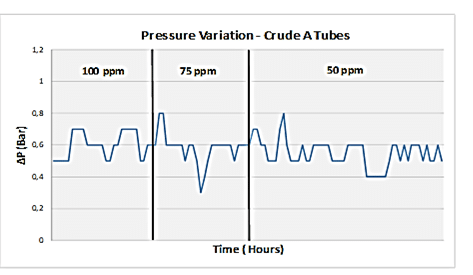

The SOLVSCALE OG 179B product was tested in the DSL system to determine its MIC (Minimum Inhibitory Concentration), the minimum dosage required to prevent scale formation. The MIC established in the lab corresponds to the recommended field dosage. The product demonstrated high efficiency at an MIC of 50 ppm, as shown in Figure 3.

The DORF KETAL R&D laboratory also conducted a comparative test using a conventional phosphonate molecule at the same dosage as SOLVSCALE OG 179B. While phosphonates are widely used for their low cost and acceptable performance, they typically show poor brine compatibility and limited thermal stability. The conventional phosphonate-based product exhibited unsatisfactory performance (pressure differential < 1 psi).

FIELD VALIDATION

After determining the MIC in laboratory conditions, SOLVSCALE OG 179B was field-tested for 90 days in a Brazilian pre-salt production unit under the following conditions:

- Water depth: 2,100 m

- Production: 100,000 BOE

- Salinity: 124,125 ppm NaCl

- Production temperature: 130°C – 145°C

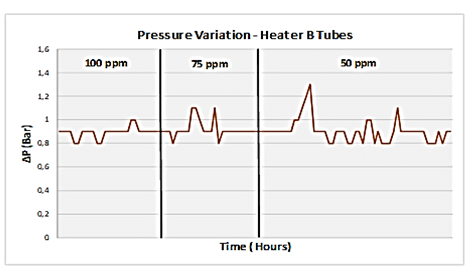

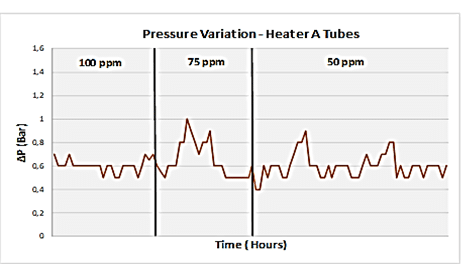

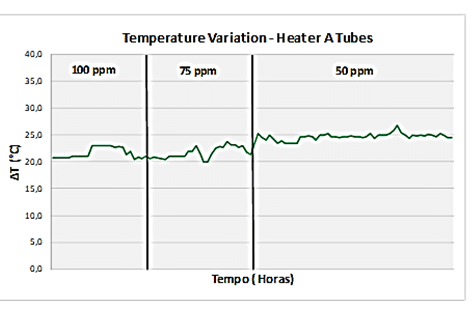

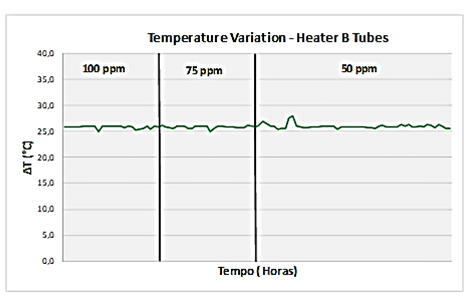

The field test began at a higher dosage of 100 ppm for operational safety reasons. During the test, the dosage was gradually reduced, as no significant variations were observed in pressure differentials or temperatures of the heat exchangers and heaters. SOLVSCALE OG 179B was therefore approved for field application at the same 50 ppm dosage validated in laboratory tests.

As shown in Figures 4, 5, and 6, no changes occurred in monitored parameters even as the dosage was reduced.

VALUE GENERATION

Following the development and successful field validation of SOLVSCALE OG 179B, DORF KETAL participated in a competitive bidding process and was awarded the contract with the best performance score.

According to customer feedback, the unit had been operating at reduced temperature due to inefficiency of the previous inhibitor, which was being injected at dosages up to 1,000 ppm.

After the application of SOLVSCALE OG 179B, it was possible to restore the original processing temperature, resulting in increased production and a dramatic dosage reduction—from 1,000 ppm down to 50 ppm. Moreover, after treatment with the DORF KETAL scale inhibitor, the unit experienced an approximate 16% increase in gross production.

___________________________________________________

__________________________________________________