INTRODUCTION

Most companies operating oil production units in Brazil currently face issues related to H2S generation in their cargo and slop tanks, due to the activity of sulfate-reducing bacteria (SRB). In addition to the occupational health hazard posed by this highly toxic gas, its corrosivity can also cause serious equipment integrity problems.

According to the specifications of most of these Operational Units, the H2S content in slop tanks must be below 10 ppm.

This case study shows the development and field application of the multifunctional biocide Syntreat OG 980B, designed specifically for this purpose.

UNDERSTANDING THE PROBLEM

The cargo tanks of production units, especially the slop tanks of FPSO-type vessels, usually have a water layer at the bottom, creating an anoxic environment conducive to developing sulfate-reducing bacteria (SRB) that generate H2S. The typical procedure operators adopt is injecting a biocidal product that prevents the proliferation of these microorganisms, resulting in better control of H2S content.

Operators previously used 75% THPS (Tetrakis Hydroxymethyl Phosphonium Sulfate) biocides applied in batches for this application. However, despite their high efficiency, this molecule is known to increase corrosion rates in injection lines severely. Besides THPS dosing as a biocide, to enhance treatment performance and broaden its spectrum of action, it is common to alternate THPS with a bacteriostatic agent, such as anthraquinone. However, this has fallen out of favor due to its high toxicity. This combination is intended to act effectively against both sessile and planktonic bacteria, but it has the disadvantage of requiring two different products.

THE SOLUTION – SYNTREAT OG 980B

Internal Development

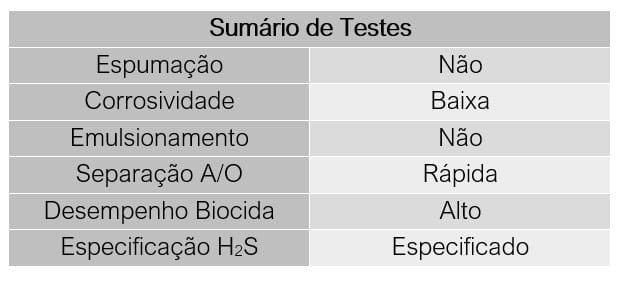

Initially, the product was developed at DORF KETAL’s R&D laboratory in Nova Santa Rita/RS, based on technical requirements from one of Brazil’s largest oil production unit operators. The Syntreat OG 980B product underwent rigorous testing protocols to ensure the following properties:

- No foaming.

- Exhibit low corrosivity compared to conventional treatment with THPS, which does not tend to stabilize the emulsion.

- Does not interfere with the system’s water/oil separation treatment.

- Exhibit high performance.

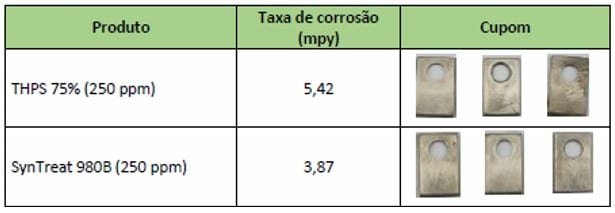

Comparative corrosivity tests between Syntreat OG 980B and THPS 75% showed that, even at high dosages, Dorf Ketal’s technology is minimally aggressive to equipment, presenting corrosion rates 30% lower compared to THPS 75%.

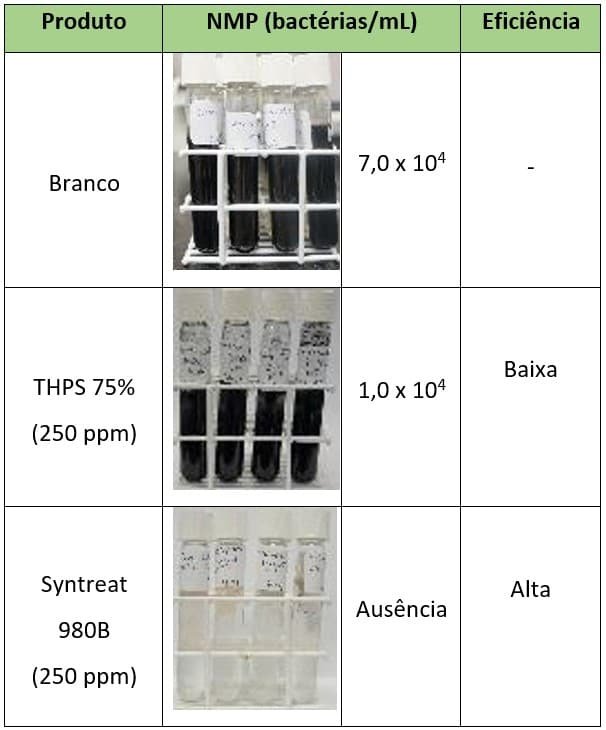

Biocide performance tests for this critical case showed that 75% THPS did not provide satisfactory efficiency. In contrast, Syntreat OG980B exhibited high efficiency, with no microbial growth observed, as shown in Fig. 3.

FIELD PERFORMANCE

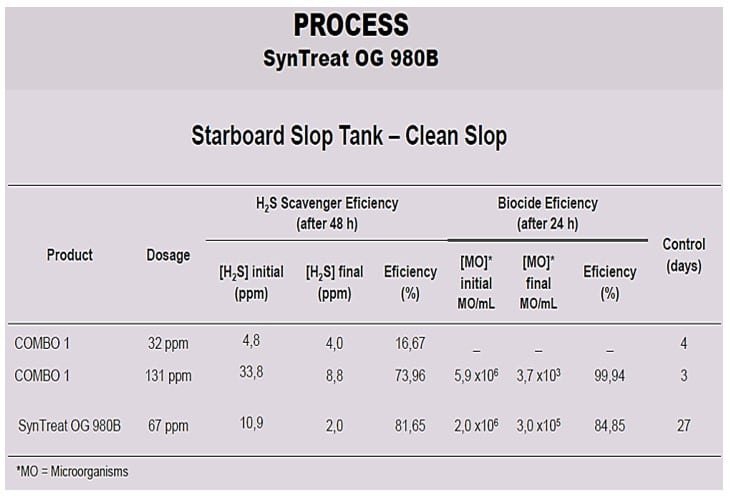

Syntreat OG 980B was tested in an FPSO-type Production Unit in the Santos Basin (Brazil) pre-salt region.

The efficiency of Syntreat OG 980B was monitored for approximately 30 days according to the following protocol:

- Monitoring of microorganism concentration through Adenosine Triphosphate (ATP) quantification.

- Monitoring of H2S concentration.

- The test was performed in comparison with a competitor product.

VALUE GENERATION

The test performed with SYNTREAT OG 980B was conclusive regarding MIC (minimum inhibitory concentration), as it showed greater efficiency at lower dosages than the current treatment used by the Unit.

In addition, Syntreat OG 980B provided seven times longer campaign duration between product batches than the competitor’s COMBO PRODUCT 1, keeping H2S levels below 10 ppm for a more extended period than the Unit used to operate. This represents a significant operational safety gain, as fewer batches mean a lower risk of incidents or accidents onboard during shock treatment operations.

Syntreat OG 980B enabled a biocide treatment cost reduction of over 70%, thus improving platform productivity indicators.