INTRODUCTION

In many Brazilian oil fields, the presence of hydrogen sulfide (H₂S) has been noted. This occurrence is particularly common in post-salt reservoirs, although it is not limited to these types of formations.

As is well-documented in the literature, H₂S is an extremely toxic gas that poses risks to both equipment and pipeline integrity, as well as to occupational safety. This gas is produced through geological processes involving various physicochemical and microbiological mechanisms.

One of the primary microbiological processes that leads to H₂S formation is driven by sulfate-reducing bacteria (SRB). These bacteria often enter reservoirs when chemical treatments, such as biocides, are not used to control their growth during secondary recovery operations involving water injection.

H₂S SCAVENGER PRODUCTS

In the oil and gas industry, various types of molecules are traditionally used to treat high concentrations of hydrogen sulfide (H₂S) in production units or extraction fields. The most commonly used compounds include triazines and glyoxal, among others.

One of the largest Brazilian operators has requested the replacement of triazine-based H₂S scavengers due to the negative impacts on refining units, particularly in the kerosene and naphtha sections of atmospheric towers, which are influenced by temperature fluctuations. Additionally, triazines have caused damage to internal components of isoprene production units in petrochemical plants.

Triazine-based products also pose challenges in exploration and production (E&P) operations, especially when injected into multiphase production systems, such as subsea injection. The primary concern is that the use of triazine increases the system’s pH, thereby increasing the potential for scaling.

Currently, triazine is only used in offshore production units during offloading operations (i.e., the discharge of oil from vessels) for specified oil with an allowable basic sediment and water (BS&W) content of less than 1%. In this particular application, where rapid H₂S reduction is crucial, triazine-based products are preferred for their rapid scavenging kinetics.

While glyoxal is still utilized in some onshore production units in Brazil, it has no application in offshore settings. This limitation is primarily due to glyoxal’s inferior kinetic performance compared to triazine and its high corrosivity, which makes it impractical in units not designed with corrosion-resistant materials. Furthermore, glyoxal-based products require a minimum of 5% water content to react effectively, a condition not present in all producing wells. Additionally, glyoxal products are considerably more expensive than other classes of H₂S scavengers.

In response to industry needs, a new class of molecules—known as “non-nitrogenated”—has been developed to achieve effective H₂S scavenging, low corrosivity, non-scaling properties, and reduced costs. In this context, DORF KETAL introduced the MAXSCAV™ OG 523B product.

THE SOLUTION – MAXSCAV™ OG 523B

DORF KETAL, with the support of its Research, Development, and Innovation Center located in Nova Santa Rita, Rio Grande do Sul, has developed MAXSCAV™ OG 523B. This product has several key features:

- Non-nitrogenated molecule

- High performance

- Cost-effective

- Non-corrosive (pH > 7.0)

- Certified for subsea applications

- Does not increase the potential for system scaling

- Fully compatible with other primary treatment products

As a result of DORF KETAL’s commitment to delivering high-performance and cost-effective solutions, MAXSCAV™ OG 523B received approval following laboratory testing conducted at the research center of Brazil’s largest oil operator.

FIELD PERFORMANCE

After receiving approval from the client’s laboratory, MAXSCAV™ OG 523B underwent field trials to verify its effectiveness in real production conditions. The chosen test site was a post-salt FPSO (Floating Production Storage and Offloading) located in the Campos Basin of southeastern Brazil.

Field characteristics during testing:

- Production: 150,000 barrels/day

- H₂S in gas phase: 200 ppm

- Target H₂S: 15 ppm in gas phase

- °API: 20

- Average BSW: 50%

- Application point: producing well

- Well temperature: 62 °C

- Application method: via gas lift (continuous)

- System: multiphase

- H₂S measurement: online

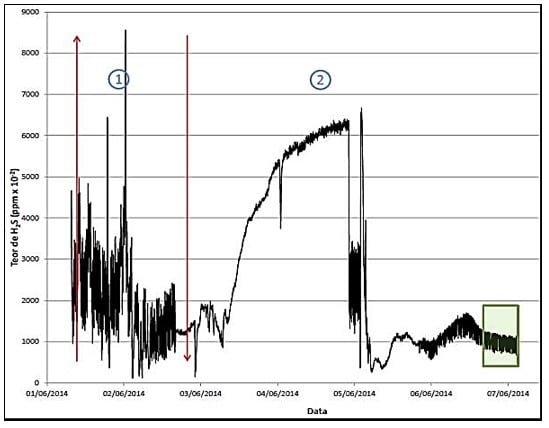

During the field test, MAXSCAV™ OG 523B was compared to three other similar commercial products. Throughout the chemical treatment period, the DORF KETAL product consistently exceeded expectations by maintaining hydrogen sulfide (H₂S) concentrations in the gas below 15 ppm, while requiring a lower dosage than previously used with the competitor, referred to as “Company A.”

In addition to the outstanding performance of MAXSCAV™ OG 523B, the processing plant remained stable throughout the test, with all fluid parameters meeting the specifications required by Brazil’s environmental regulatory agencies. This confirmed that DORF KETAL’s H₂S scavenger was fully compatible with other primary treatment chemicals and did not cause any adverse environmental effects.

The minimum effective dosage for MAXSCAV™ OG 523B was 40 L/h, whereas the lowest dosage achieved by competitors (“A,” “B,” and “C”) was 12.5% higher than this.

The dosage reduction offered by DORF KETAL’s scavenger resulted in increased treatment efficiency and significant cost savings, as the product can be applied across multiple platforms and various producing wells.

VALUE GENERATION

The test conducted with MAXSCAV™ OG 523B yielded conclusive results regarding its performance, demonstrating excellent scavenging efficiency at lower dosages compared to competing market products. Following this technical validation, the product was included in a global tender for Brazil’s largest offshore operator, resulting in DORF KETAL being awarded the contract.

With this and subsequent contracts, DORF KETAL provided treatment support for more than ten platforms simultaneously, both post- and pre-salt, establishing MAXSCAV™ OG 523B as a proven solution and a recognized market reference by the client.

Recently, MAXSCAV™ OG 523B completed another field test with a different operator (IOC) active in Brazil and globally, including the North Sea region.