The Problem

A major naphtha cracking plant in Asia, with a processing capacity of 810 KTA, was facing a problem associated with the instability of pyrolysis gasoline due to the presence of high olefin content and the need to reprocess off-spec pyrolysis gasoline.

Several issues were linked to unstable gasoline, such as:

- Clogging of filters, heat exchangers, and hydrogenation reactor beds.

- Blockage of storage tank pump filters.

- Gum formation during transportation of C9+ products to local industries.

The plant was losing profit margins due to customer complaints about the quality of the C9 solvent and restrictions on reprocessing off-spec pyrolysis gasoline.

The Solution

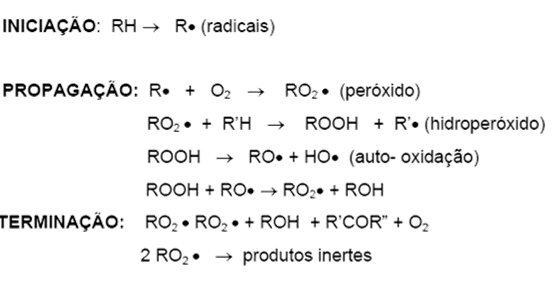

After detailed analysis, the main problem was found to be associated with the oxidation mechanism of polymerizable species. The mechanism below illustrates the nature of the issue.

Dorf Ketal approached the client with the recommendation of a specially formulated antioxidant designed to control fouling in gasoline stabilization systems. A proposal was submitted and followed by laboratory evaluation. After successful washed gum laboratory tests, the product was approved for plant use.

The Result

Significant benefits were achieved from the chemical application by reducing washed gum values to below 5 mg/100 ml (market specification), including:

Prevention of gum formation. This helped the plant meet C9 specifications and proved to be economically very beneficial, as product supply to various local industries using C9 as fuel in small-scale heaters and furnaces increased.

Increased profitability. With the help of the additive, the plant can now reprocess off-spec pyrolysis gasoline and different unstable gasoline streams from other olefins plants.

For more information on Dorf Ketal’s antioxidant technologies, please contact us.