INTRODUCTION

A liquid cracker in Southeast Asia faced downstream polymer-plugging challenges following the Caustic Tower. The Plant has 500 KTA of Ethylene capacity and is a long-term partner of DORF KETAL.

DORF KETAL conducted a root cause analysis with the customer, identifying the fouling precursors and adequately addressing the problem by using an improved version of the ACtyfix DA 2600 antifoulant Series.

PROBLEM DESCRIPTION

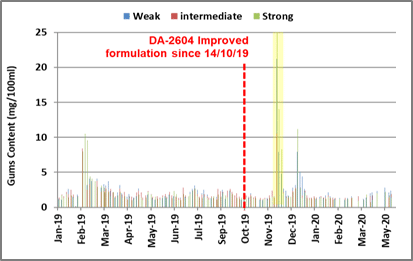

Although red oil generation was under control in the Caustic Tower, as shown in Figure 1, the Plant faced polymer plugging problems in downstream equipment, specifically in the De-oiling Drum and Spent Caustic Tank.

Therefore, DORF KETAL has started investigating polymer precursors and potential solutions to combat them.

ROOT CAUSE ANALYSIS

DORF KETAL has conducted several laboratory analyses to understand the root cause of the problem. It was found that the polymer gums collected in the Spent Caustic Tank were only around 50% soluble in Dichloromethane (DCM – the usual solvent for red oil polymers) and were identified as an unterminated aldol by FTIR analysis.

Based on that, Dorf Ketal specialists suspected that the long residence time in the De-oiling Drum had led to oxidation and dehydrogenation of the polymers inside the tank, forming a new insoluble layer at the interphase between the spent caustic and gasoline phases. A similar problem was seen by DORF KETAL in an Indian cracker and resolved with an improved ACtyfix DA 2600 Series formulation.

ACtyfix DA 2600 Series is patented chemistry from DORF KETAL, which is applied worldwide to control the polymerization of carbonyls, also known as red oil polymers, in Caustic Towers. Hence, the improved formulation of the red-oil inhibitor was offered to the Southeast Asia Plant, which was approved by the customer.

PERFORMANCE RESULTS

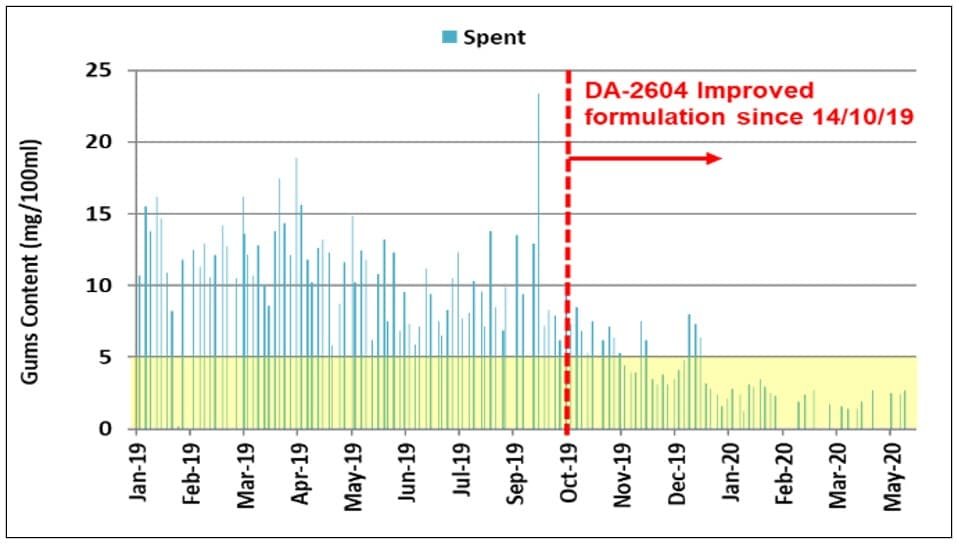

With the improved antifoulant injection, the Plant has observed gradual improvements in spent caustic gums:

- Spent caustic gums have shown a significant reduction of more than 60%, as shown in Figure 2.

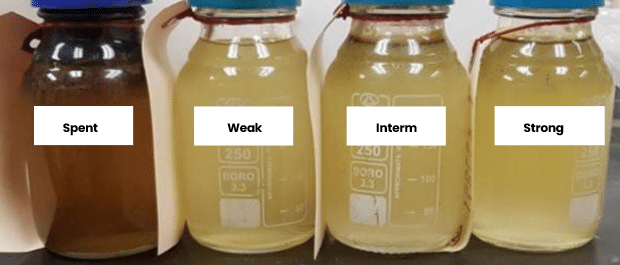

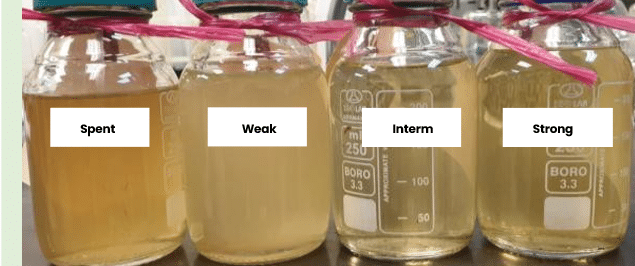

- Additionally, improvement is seen in the appearance of spent caustic samples before and after the introduction of improved formulation – details in figures 4 and 5.

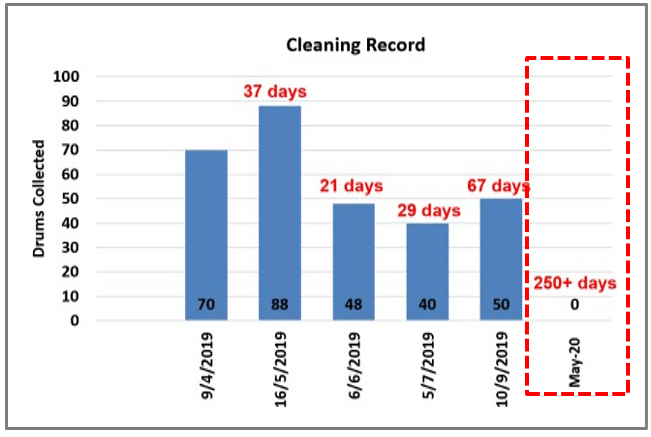

Since the introduction of improved ACtyfix DA 2600 Series treatment, the insoluble layer interphase buildup has stopped, eliminating the polymer-draining concern and reducing the frequency of tank cleaning (Figure 3), reducing the cost of waste disposal and Plant maintenance.

RETURN ON INVESTMENT (ROI)

With the improved ACtyfix DA 2600 Series formulation, the gum content in spent caustic has been dramatically reduced, eliminating the insoluble polymer layer that accumulates in the system. This improvement has been granted to the Plant:

- Reduced the spent caustic WSIS incinerator operation.

- Reduced draining frequency, resulting in less exposure to people.

- Reduced waste disposal and maintenance costs.

- Increased efficiency and reliability of the spent caustic treatment unit.

- Estimated savings related to waste disposal are around 35-40 KUSD per year, and additional USD savings of a few thousand from Tank Cleaning.