INTRODUCTION

After startup, a major ethylene plant in Latin America experienced a severe fouling problem at the Quench Oil Tower. Upon consultation with the licensor, the plant engineers contacted DORF KETAL to initiate antifoulant treatment. The primary goal was to maintain the fouled column’s operation for the remainder of the campaign, expected to last an additional 2 years, without requiring any maintenance shutdowns.

Once this initial objective was achieved, DORF KETAL was tasked by the customer to enhance the run length of the Quench Oil Tower by more than 100%. This improvement was aimed at ensuring polymerization control in the rectification section without limiting throughput.

UNDERSTANDING THE MECHANISMS BEHIND THE CHALLENGE

According to the literature, pyrolysis gasoline contains several components, such as styrene, indene, and divinylbenzene, that can readily react and form polymers. When exposed to high temperatures or metallic ions, these compounds can polymerize and rapidly accumulate on trays and internal surfaces. This fouling can increase the pressure drop (Delta P) across the column, negatively impacting gasoline fractionation, the column’s temperature profile, and quench oil viscosity control. If not properly managed, fouling in the rectification section can result in decreased plant throughput and unplanned maintenance shutdowns.

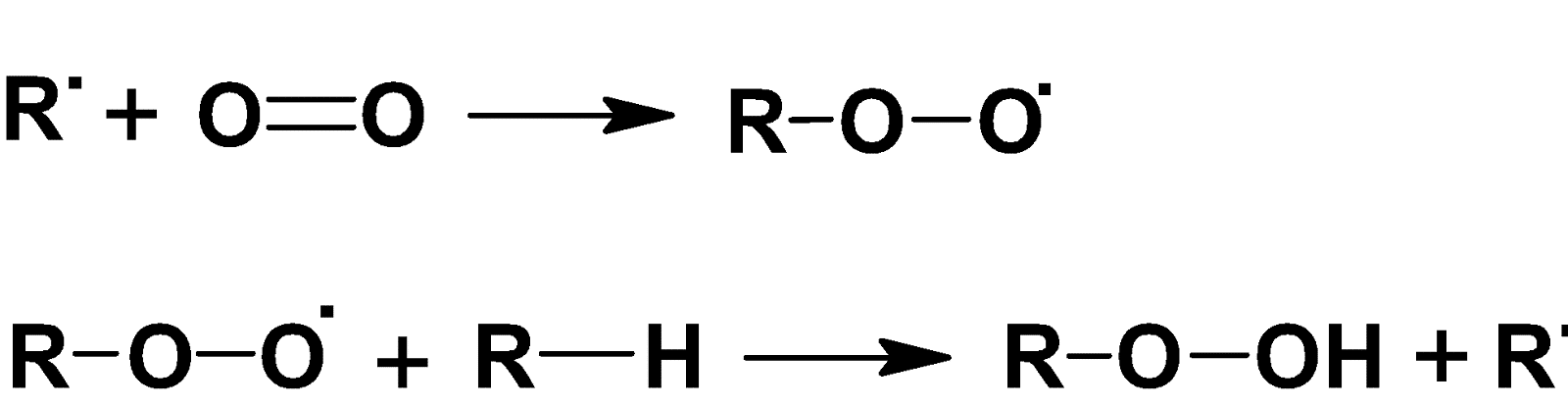

The primary mechanism of polymerization observed in the rectification section of the Quench Oil Treatment (QOT) is the Free Radical Mechanism, which consists of three steps: Initiation, Propagation, and Termination.

The initiation step involves the generation of free radicals via hemolytic fission. High temperatures can trigger the formation of free radicals, and the presence of metallic ions can further catalyze this process. The radicals formed, called initiators, can react in two ways depending on whether oxygen is present.

The second step of polymerization, known as propagation, involves the formation of a polymeric structure with a low crosslinking ratio. This structure isolates the free radicals, allowing them to grow without termination. Propagation can occur in two different ways. In the presence of oxygen, the free radicals quickly react with oxygen to form peroxide radicals. At high temperatures, these peroxide radicals facilitate the propagation of free radicals, leading to longer polymer chains. In the absence of oxygen, the initiator reacts with a monomer, creating a longer radical.

This process continues at a constant rate, denoted as Kp. Overall, propagation is a vital step in polymerization that contributes to the development of polymer chains.

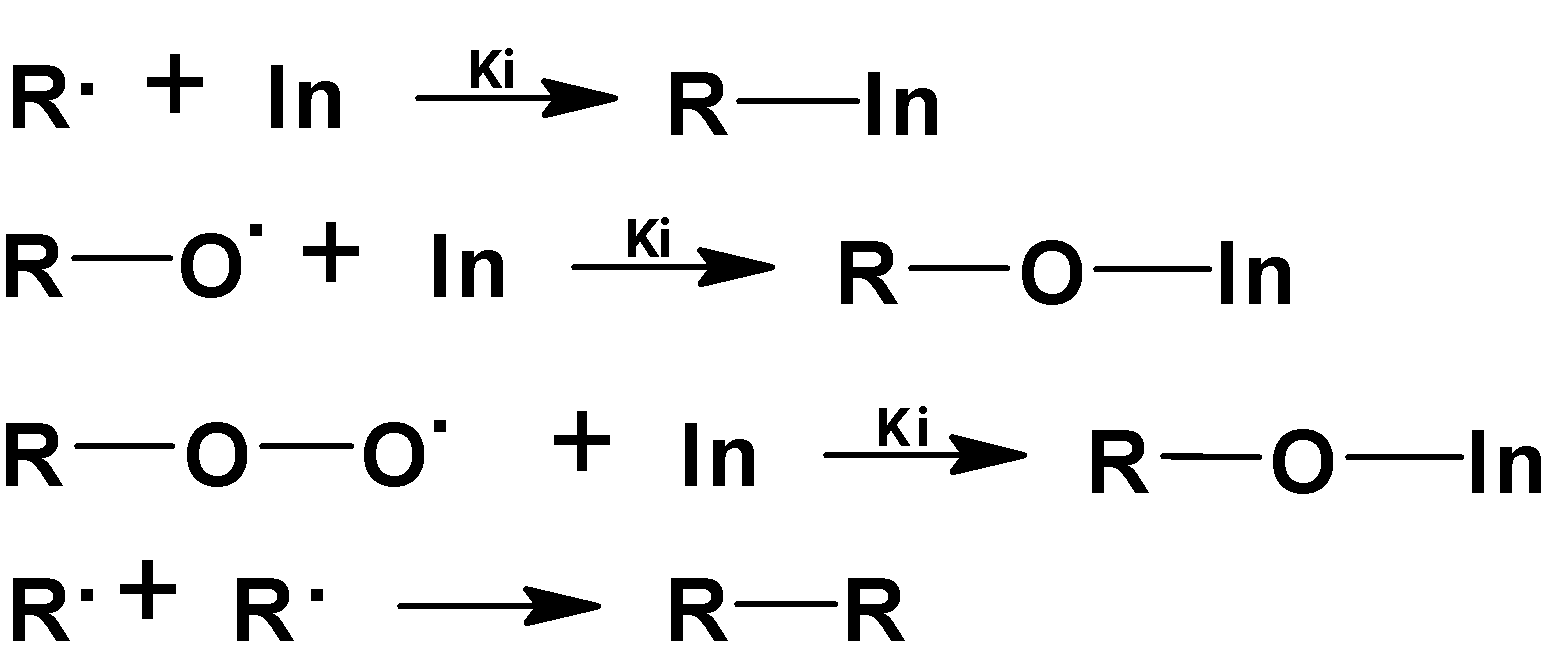

The final step of the polymerization process is the termination, in which the destruction of the reacting center occurs. Two distinct agents can originate from this destruction. It can be caused by either an inhibitor, which reacts with the initiator or the peroxide, transforming them into non-radical species, or by the own polymeric propagation chain.

Indene is a highly reactive compound found in the rectification section of the Quench Oil Tower. It can undergo free-radical polymerization, leading to the formation of polycyclic polymers—a common fouling issue in this section.

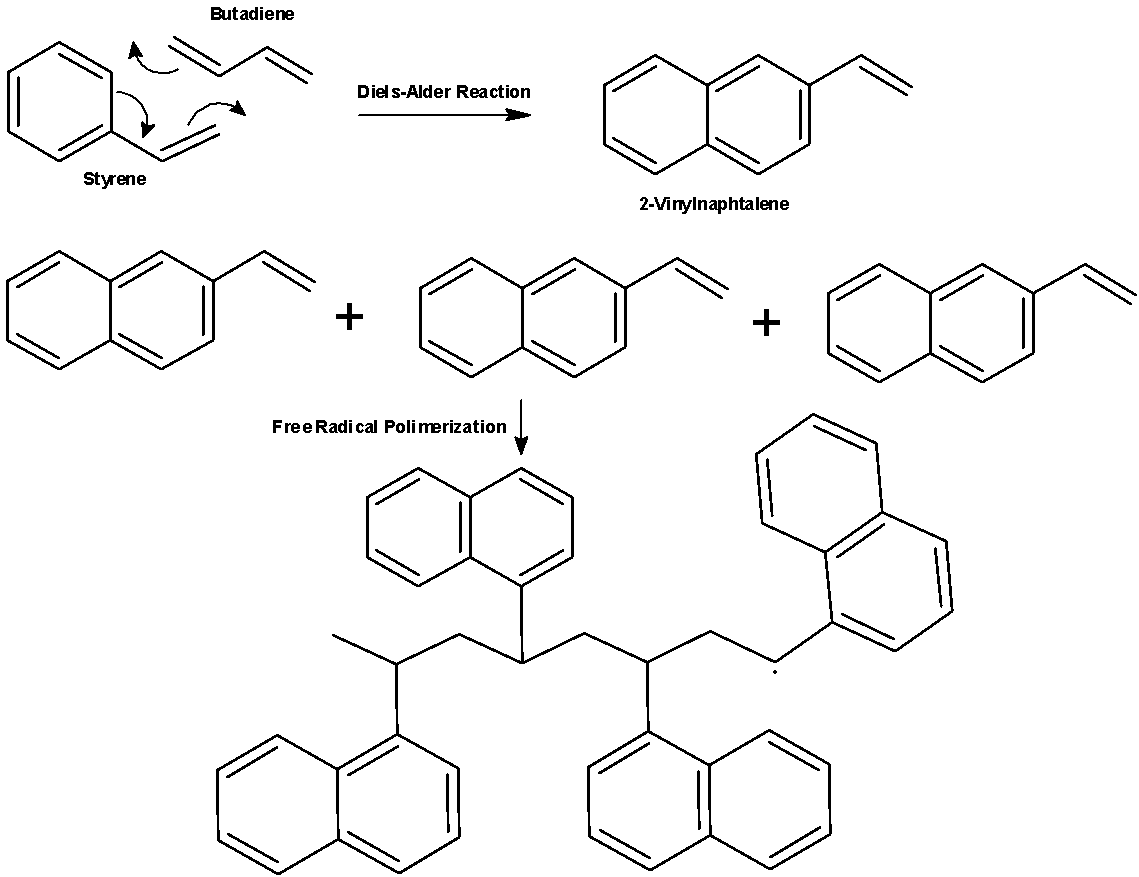

In the rectification section of a Quench Oil Tower, a secondary polymerization mechanism can occur due to the presence of numerous dienes. This mechanism is known as the Diels-Alder condensation. It involves the 1,4-addition of an alkene to a conjugated diene, forming a cyclic compound. In this section, the Diels-Alder reaction can produce 2-vinyl naphthalene, which can subsequently undergo polymerization via a free-radical mechanism.

CONTEXTUALIZING THE SYSTEM

This Liquid Cracker features a Quench Oil Tower with twenty-four (24) trays. Trays #1-#10 correspond to the rectification section. The highest concentration of polymers is typically found in trays #7 and #8, where light fuel oil (LFO) withdrawal also occurs.

In the first two years, no antifoulant treatment was applied to this column; however, the fouling tendency was already very high, as shown in Figure 1. In addition to the regular trend of polymerization, gasoline quality begins to decline due to poor fractionation. This decline leads to an increase in monomer concentration, influenced by gasoline reflux, as well as a reduction in LFO withdrawal, a process typically implemented to help control bottom viscosity.

Fouling formation significantly impacts the temperature profile. It increases the demand for quench/intermediate oil and gasoline reflux, making it more challenging to maintain the column specifications within project conditions.

PROPOSED TREATMENT

As demonstrated above, addressing the fouling problem is quite challenging. It requires not only an effective chemical agent but also the continuous monitoring and adjustment of critical variables. DORF KETAL has chosen ACtyfix DA 2326, an antifoulant blend of free radical inhibitors and antioxidants, to tackle this issue. The product is injected at the pyrolysis gasoline reflux point, ensuring it reaches the most critical area of the rectification section. ACtyfix DA 2326 is used globally to control polymerization in Quench Oil Towers and is recognized as an exceptional chemical, even in units that already show symptoms of fouling.

In addition to using ACtyfix DA 2326, DORF KETAL has implemented a robust monitoring strategy for critical system variables. A key indicator in this strategy is the Tower “Fouling Factor”, which correlates the tower’s pressure profile with the flow of liquid and gas through the trays. A rising trend in this indicator suggests that fouling is developing within the system. The team also monitors the reflux ratio in the rectification section, aiming to meet a specific project target, and tracks the percentage of light fuel oil (LFO) withdrawn relative to the feed to ensure a controlled quantity of monomer. Accumulated naphthalene, a naturally occurring compound monitored during LFO withdrawal, can produce foam, increasing the risk of carryover.

Additionally, DORF KETAL monitors the tower’s temperature profile to control stripping of lighter compounds and internal refluxes, which help assess the viscosity of the quench oil.

DORF KETAL also leverages its laboratory infrastructure to analyze certain properties of pyrolysis gasoline and light fuel oil to enhance monitoring. The concentration of naphthalene in the pyrolysis gasoline is analyzed alongside its boiling point. A successful treatment would be reflected in an improved boiling point of the pyrolysis gasoline, indicating better fractionation. For light fuel oil, the concentrations of naphthalene and polymers are also closely monitored.

RESULTS AND BENEFITS OF THE TREATMENT

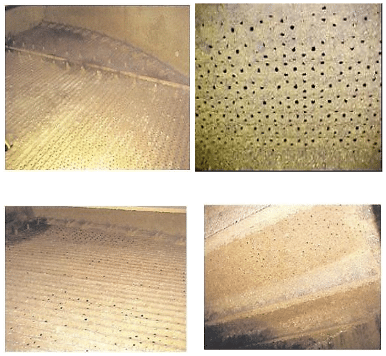

Due to DORF KETAL’s polymerization treatment, the Plant operated effectively until its first scheduled maintenance. Upon inspection, the equipment showed almost no signs of fouling, confirming the high quality of both the product and the service.

By meeting the treatment’s objectives, the Plant was able to operate without any throughput limitations, ensuring the company’s revenue for an additional two years. Following this initial campaign with DORF KETAL’s treatment, the Plant was optimistic about achieving a longer run length and subsequently implemented the ACtyfix DA 2326 antifoulant program to tackle upcoming challenges.

Since then, DORF KETAL has performed chemical treatments on the Quench Oil Tower, allowing the Plant to set run-length records of 6 and 6.5 years in its second and third campaigns, respectively, all without experiencing any throughput limitations.

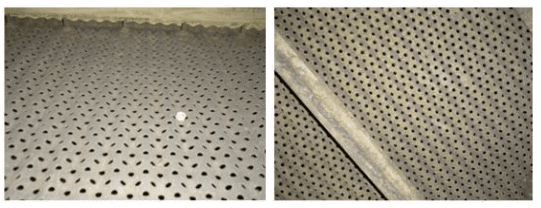

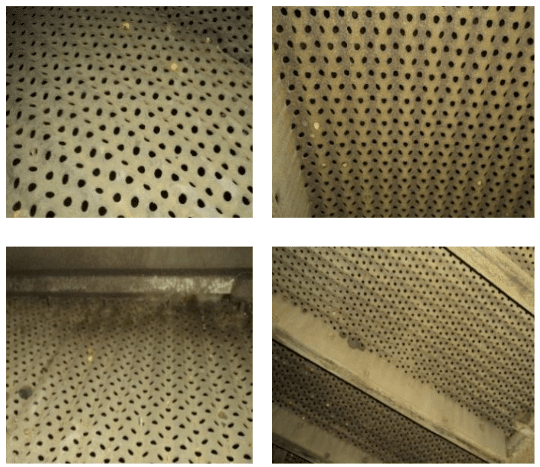

Figures 2 and 3 illustrate the inspection results from the rectification section during the turnarounds, showcasing the impressive outcomes achieved with the ACtyfix DA 2326 treatment.

The trays were remarkably clean, allowing maintenance to be performed without removing all the plates. This approach saved a significant amount of time and money, particularly for equipment deemed critical to the turnaround schedule.