INTRODUCTION

A Latin American Gas Cracker faced several issues related to phase separation in the knock-out (KO) drums of the Cracked Gas Compressor (CGC), directly affecting the Quench Water quality and the Hydrocarbon separation. The Unit processes Ethane as feedstock and has a 1000 KTA of Ethylene capacity.

DORF KETAL was already responsible for treating Quench Water (QW) and Dilution Steam Generation (DSG) systems and has started a Root Cause Analysis with the customer to understand and mitigate the problem.

PROCESS DESCRIPTION AND PROBLEM STATEMENT

The Unit is a five-stage CGC, with the Caustic Tower in 4th stage discharge. The water and condensed hydrocarbons return from all stages to the 1st stage KO Drum, where the water is re-routed to the Quench Water Tower, and the hydrocarbon is sent to treatment. Since the Plant startup, DORF KETAL has been treating the Quench Water system without the need for continuous injection of an emulsion breaker.

After replacing the Wash Oil injected into the CGC casing, the quality of the quench water sample decreased significantly, causing an increase in the saturation of pre-filters and coalescer elements, as well as fouling and under-deposit corrosion in the DSG reboilers. Besides the higher operational costs, the Plant did not meet its efficiency KPIs. The DSG blowdown was higher than the project, and high-quality direct steam to the Dilution Steam header was required due to the reboilers’ inefficiency.

During the Root Cause Analysis, it was discovered that the new wash oil consumed has a relative density very close to the water, creating a challenge for the phase separation in the KO Drum. Because of that, the quality of the water re-routed to Quench water decreased, creating an intense emulsion in the QW oil/water separator.

PROBLEM MITIGATION

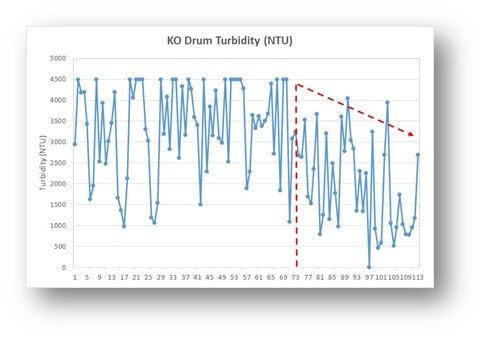

Since the emulsion in the KO drum was identified, the Plant has worked on operational improvements to the hydrocarbon draining procedure. Figure 2 presents the water sample turbidity before and after the operational improvements. The sample appearance can be checked in Figure 3.

Even after the operational improvements, the separation in the KO drum was still insufficient to avoid prejudices about the Quench Water and hydrocarbon systems. Hence, DORF KETAL has developed several Lab studies with field samples to identify a Reverse Breaker capable of separating an emulsion with two streams of very relative density.

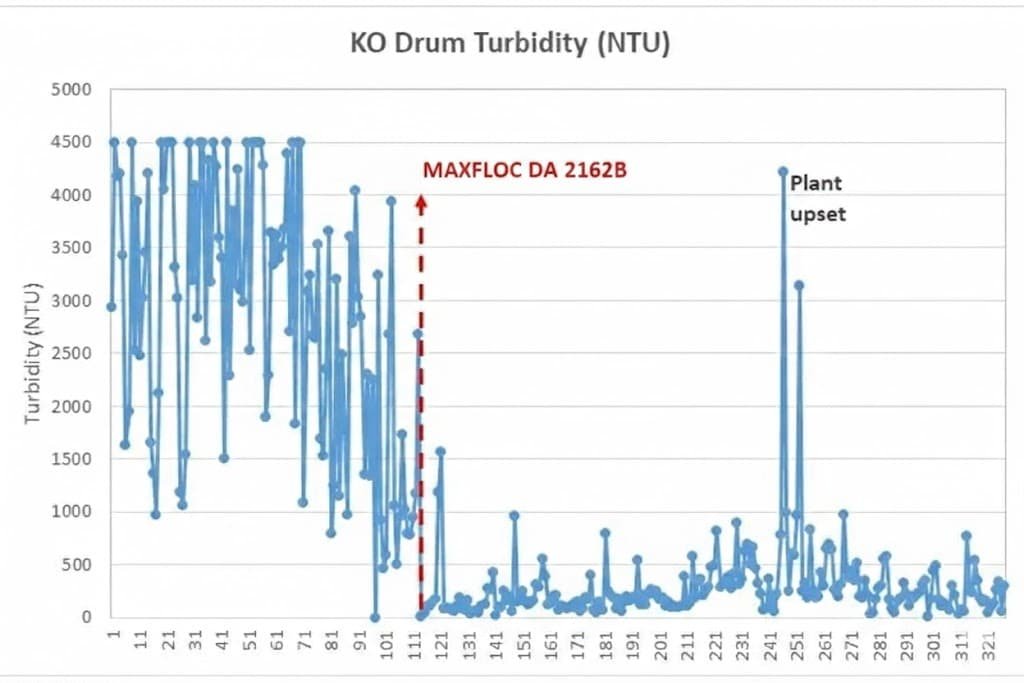

The reverse breaker selected was the MAXFLOC DA 2162B, and the injection point recommended was the liquid return from the 2nd stage KO drum to the 1st stage KO drum, where the phase separation must occur.

The impact on the water turbidity was immediate after MAXFLOC DA 2162B treatment. Since then, the turbidity has been kept under 1000 NTU, which means it is four times lower than before the treatment (Figure 4). The sample appearance also represents the improvement granted by adding the DORF KETAL’s reverse breaker, as seen in Figure 5.

RETURN ON INVESTMENT (ROI)

The emulsion breaking treatment applied in the CGC KO drum, MAXFLOC DA 2162B reverse breaker, was able to grant several benefits and savings to the Plant. The investment in the treatment was not only wholly paid, but the Plant was able to save a significant amount on OPEX. Some of the savings’ items are listed below:

- Increase in filters and coalescer’s elements run length (less replacement).

- Reduction in DSG reboiler cleaning and maintenance costs.

- Less effluent generation in DSG blowdown.

- Reduction in steam injection into Dilution Steam header.

- Improved hydrocarbon system operation, reducing the amount of water being separated and the need for external treatment.

Besides the items described, it is essential to highlight that several aspects related to personal and environmental exposition were also improved since the effluent generation of the Plant was significantly reduced, as well as the interventions in the process (pre-filters, filters, heat exchangers, etc.).

The partnership between the customer and DORF KETAL was pivotal to this successful result, combining the operational and chemical efforts to achieve and overcome the established KPIs.