INTRODUCTION

In the pursuit of the “whitest white” paper, it has become increasingly necessary to use optical brighteners in the production of white paper, due to the growing demand for higher levels of whiteness in the final product.

On the other hand, success in using this technology depends on several process factors that must be evaluated, monitored, and controlled in order to maximize results with the lowest possible consumption.

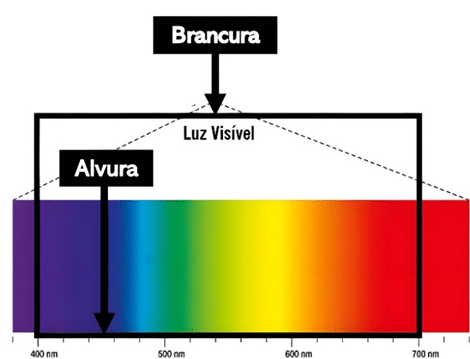

Basically, optical brighteners (or whiteners) are sulfonate-based chemicals that enhance the whiteness of a substrate by converting ultraviolet light waves into blue light. Human vision perceives only a small portion of the electromagnetic radiation spectrum of light, expressed in wavelength (nanometers); this portion is called the visible spectrum and ranges from 380 nm (ultraviolet limit) to 780 nm (infrared limit).

Natural cellulose fibers, ubiquitous in papermaking, tend to absorb blue radiation and therefore appear yellowish.

A whitening agent artificially compensates for this loss (as blue and yellow, being complementary colors, neutralize each other). Optical brighteners are molecules that absorb electromagnetic radiation between 300 and 400 nm (therefore outside the visible spectrum) and re-emit it in the visible spectrum between 400 and 500 nm (corresponding to blue). This phenomenon is called fluorescence. As a result, paper appears whiter and brighter due to its fluorescent effect.

THE CHALLENGE

A tissue and hygiene paper mill located in southern Brazil, with a production capacity of approximately 23 tons of paper per day, used about 1.8 kg/ton of disulfonic optical brightener in the pulp. The company sought to optimize the paper whitening process. After discussions with the Dorf Ketal technical team, the following goals were agreed upon with the client: increased paper whiteness and reduced treatment costs.

PROJECT SCOPE

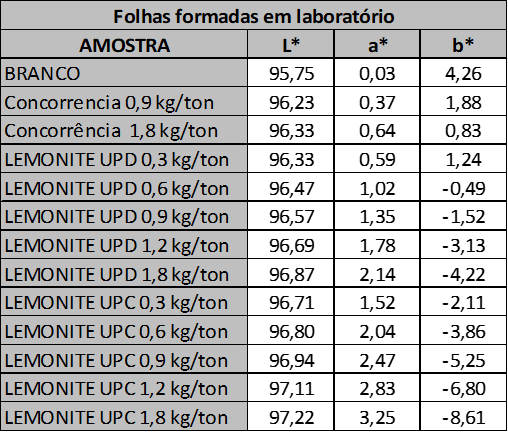

All additives and products added to the papermaking process can contribute either negative or positive charges. Based on this premise, the first step was to map the application of all process additives, considering the application point and dosage. Subsequently, a screening was performed with different types of optical brighteners from the current LEMONITE X line used by the client. The product was applied to the pulp in different dosages, and the resulting sheet was analyzed for whiteness, brightness, and L,a,b coordinates using an instrument called ELREPHO, as illustrated in Fig. 2.

RESULTS

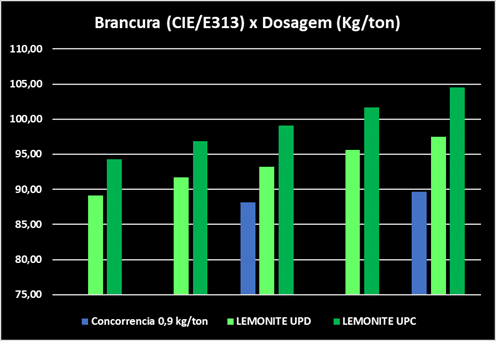

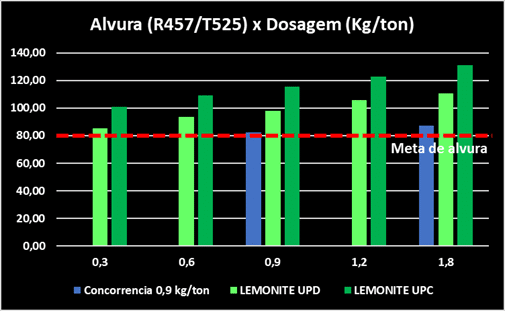

As shown in Figures 3 and 4, a significant increase in whiteness and brightness was observed when applying LEMONITE UPD and LEMONITE UPC compared to the competing optical brightener. The competitor’s product showed greater saturation tendency than the LEMONITE line, with a saturation index at a dosage of 1.8 kg/ton.

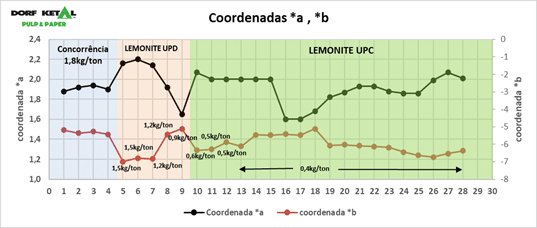

In Figure 5, it can be seen that the competitor’s product shows lower values for the L, a, and b coordinates, as well as for brightness and whiteness. The LEMONITE line resulted in a more bluish paper, indicating a possible reduction in the need for tinting agents in the process.

Based on the laboratory results, an industrial test was conducted to evaluate the performance of the LEMONITE UPD and LEMONITE UPC optical brighteners in the production process.

INDUSTRIAL EVALUATION

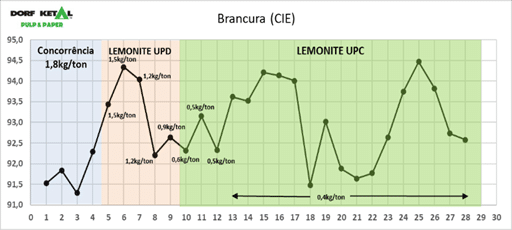

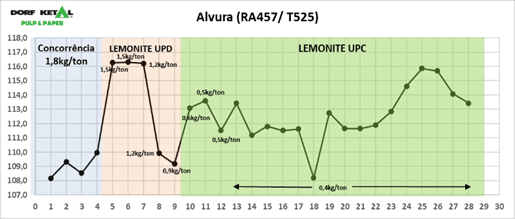

The graphs in Figures 6, 7, and 8, obtained from field tests, confirm the results observed in the laboratory.

Using 0.5 kg/ton less optical brightener than the competitor’s product, LEMONITE UPD showed, on average:

- An increase of 4% in brightness and 1.7% in whiteness;

- An increase of 5.2% in the *a coordinate and 14% in the *b coordinate modulus.

Using 1.4 kg/ton less optical brightener than the competitor’s product, LEMONITE UPC showed, on average:

- An increase of 3.2% in brightness and 1.4% in whiteness;

- An increase of 11.9% in the *b coordinate modulus.

CONCLUSION

The ongoing pursuit of higher paper whiteness has driven the industry to adopt optical brighteners as a solution. Tests carried out in both laboratory and industrial environments demonstrated the superior effectiveness of the LEMONITE line compared to the competing product. Notably, LEMONITE products not only improved paper brightness and whiteness but also allowed dosage reduction, translating into savings and process efficiency.

The benefits of using LEMONITE brighteners go beyond the visual improvement of the product. The more bluish appearance of the paper, resulting from the increase in the *b coordinate modulus, suggests potential savings in tinting agents. Furthermore, minimizing paper loss due to quality rejection, achieving higher added value in sales, expanding the customer base, and obtaining a more favorable cost-benefit ratio are significant gains for the paper mill.

Ultimately, the results achieved with the LEMONITE line highlight the importance of selecting the right optical brightener to enhance paper quality and optimize the manufacturing process. The client’s decision to adopt LEMONITE UPD as a permanent replacement for the previously used product is a strong testament to the effectiveness and advantages offered by this innovative solution.

For more information, contact your nearest DORF KETAL specialist.