CHALLENGE

A major oil and gas company operating in northern Alberta, Canada, traditionally used hydrochloric acid (HCl) to remove calcium carbonate (CaCO₃) scale from wells under circulating steam conditions, where bottomhole temperatures reach approximately 150°C (300°F). The operator had a long history of facility upsets caused by the transfer of spent acid containing high levels of dissolved iron, which precipitated due to HCl’s strong acidity, leading to significant shutdowns and costly production losses. The use of expensive chelating agents or the disposal of spent acid was the standard mitigation procedure.

SOLUTION

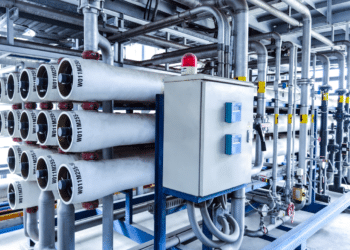

Oil and water samples from area wells were tested for compatibility with the modified acid Enviro-Syn® HCR-6000. A customized formulation was prepared with additional additives to optimize performance. The recommended treatment involved using Enviro-Syn® HCR-6000 to clean the wellbore and formation, remove scale, and increase production rates, due to its low corrosivity at elevated temperatures and inherent chelating properties—eliminating the need for costly supplemental chemistry to control iron precipitation.

The HCR-6000 package was transported in concentrated form and diluted to 50% with produced water on site. The acid mixture was then injected down the casing to treat the perforated liner in the horizontal section of the well.

Enviro-Syn® HCR-6000 was nitrified to assist diversion along the lateral section of the well. Once the full volume was placed, it was overdisplaced and allowed to soak for 24 hours at formation temperature (without cooling).

RESULTS

Enviro-Syn® HCR-6000 effectively sequestered ferric chloride (FeCl₃) and dissolved all calcium carbonate scale. While HCl tends to precipitate FeCl₃ at low pH (~2), Enviro-Syn® HCR-6000 typically maintains a residual pH of around 4.5 without any precipitation of iron, calcium, or other solubilized minerals. The wells were successfully brought back online with no facility shutdowns or interruptions.

Typically, acid stimulations are followed by costly facility upsets, resulting in thousands of dollars in downtime, lost production, and disposal costs. The use of Enviro-Syn® HCR-6000 eliminated this risk thanks to its inherent chelating properties, allowing Free Water Knock-Out (FWKO) interface probes and treatment systems to function normally, preventing high- and low-level shutdowns. HCR-6000 proved to be a highly cost-effective method for the operator to stimulate wells, increase production, and maintain facility integrity while using a safe, low-corrosion alternative to HCl.

___________________________________________________

___________________________________________________