CHALLENGE

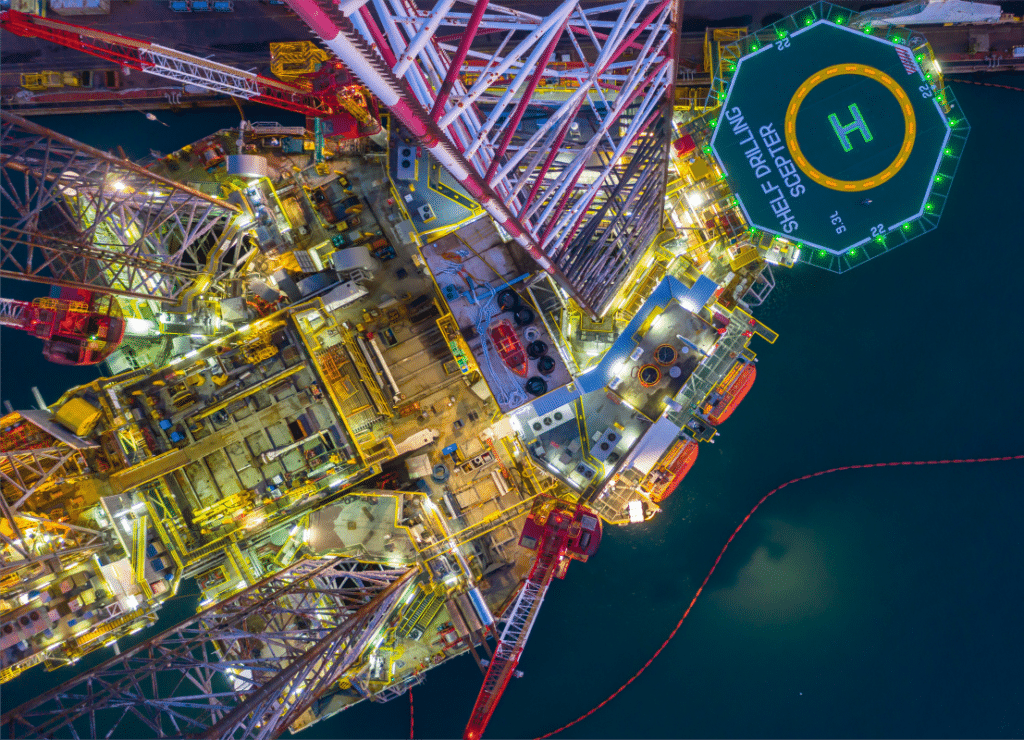

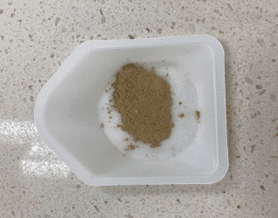

A major operator in West Africa faced suboptimal production in an offshore oil well. Investigations revealed that scaling was restricting flow. Scale samples (figure on the side) were collected and analysis indicated predominantly calcium carbonate (CaCO₃) with some acid-insoluble clays and organic materials originating from formation water precipitation and drilling fluids. The operator required a scale dissolver with high dissolution capacity and minimal corrosion impact, given the extended exposure time expected on downhole completion equipment composed of high-chrome alloys.

SOLUTION

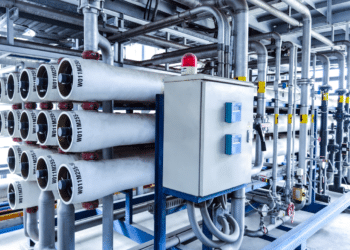

Laboratory testing was performed on several different products, including Enviro-Syn® HCR-7000 Modified Acid with an incorporated solvent to target organic components. Results showed that the scale was highly soluble in Enviro-Syn® HCR-7000 at 50°C (122°F), requiring less than 10 minutes to dissolve both the acid-soluble and organic portions of the deposit, leaving only minor insoluble residue. No visible reprecipitation occurred after seawater was added and mixed for two hours. Additionally, corrosion tests demonstrated very low corrosion rates on downhole tools and completion equipment. Enviro-Syn® HCR-7000 provides a safe and effective alternative to conventional strong mineral acids, such as hydrochloric acid (HCl), mitigating hazards like fumes and corrosive effects on skin and metals. Its unique reaction rate control offers numerous technical and operational benefits. Enviro-Syn® HCR-7000 provides dissolution capabilities comparable to 15% HCl while significantly reducing reprecipitation after injection compared to HCl treatments.

RESULTS

The operator selected Enviro-Syn® HCR-7000 for the operation due to its superior performance, health, safety, and environmental (HSE) profile, and its corrosion prevention performance meeting both operator and equipment service provider requirements.

A total of 400 m³ (2,516 bbl) of Enviro-Syn® HCR-7000 was injected via coiled tubing into the affected zones to treat and stimulate the well. The operation was highly successful, reducing the mechanical skin value from 14 pre-treatment to 0 post-treatment. This resulted in an eightfold increase in the Productivity Index for liquids—from 22 sm³/d/bar to 175 sm³/d/bar under pseudo-steady-state conditions—and a production increase of over 2,000 bpd, equivalent to approximately USD 140,000 per day in additional cash flow at $70/bbl for the operator.

___________________________________________________

___________________________________________________